Page 89 - Construction Waterproofing Handbook

P. 89

2.52 CHAPTER TWO

Glass cloth–reinforced rubber asphalt sheets, unlike self-adhering systems, require no

concrete curing time. Separate adhesive and seam sealers are available. Glass cloth rubber

sheets are typically 50 mil thick and require a protection layer for both vertical and hori-

zontal applications. Typical properties of sheet materials are summarized in Table 2.6.

SHEET SYSTEM APPLICATION

Unlike liquid-applied systems, broom-finished concrete is not acceptable, as coarse fin-

ishes will puncture sheet membranes during application. Concrete must be smoothly fin-

ished with no voids, honeycombs, fins, or protrusions. Concrete curing compounds should

not contain wax, oils, or pigments. Concrete surfaces must be dried sufficiently to pass a

mat test before application.

Wood surfaces must be free of knotholes, gouges, and other irregularities. Butt joints in

wood should be sealed with a 4-in-wide membrane detail strip, then installed. Masonry

substrates should have all mortar joints struck flush. If masonry is rough, a large coat of

cement and sand is required to smooth surfaces.

Metal penetrations should be cleaned, free of corrosion, and primed. Most systems

require priming to improve adhesion effectiveness and prevent concrete dust from inter-

fering with adhesion (Fig. 2.65).

All sheet materials should be applied so that seams shed water. This is accomplished by

starting at low points and working upward toward higher elevations (Fig. 2.66). With adhe-

sive systems, adhesives should not be allowed to dry before membrane application. Self-

adhering systems are applied by removing a starter piece of release paper or polyethylene

backing, adhering membrane to substrate (Fig. 2.67).

With all systems, chalk lines should be laid for seam alignment. Seam lap requirements

vary from 2 to 4 in (Fig. 2.68). Misaligned strips should be removed and reapplied, with

material cut and restarted if alignments are off after initial application. Attempts to correct

alignment by pulling on the membrane to compensate may cause “fish mouths” or blisters.

A typical sheet membrane application is shown in Fig. 2.69.

At changes in plane or direction, manufacturers call for a seam sealant to be applied

over seam end laps and membrane terminations (Fig. 2.70). Materials are back-rolled at all

seams for additional bonding at laps (Fig. 2.71). Any patched areas in the membrane

should be rolled to ensure adhesion.

Each manufacturer has specific details for use at protrusions, joints, and change in plane

(Fig. 2.72). Typically, one or two additional membrane layers are applied in these areas and

sealed with seam sealant or adhesive (Fig. 2.73). Small detailing is sealed with liquid mem-

branes that are compatible and adhere to the sheet material. Figure 2.74 details a typical col-

umn foundation waterproofing application. Figure 2.75 shows the proper treatment of a

control or expansion joint using sheet systems.

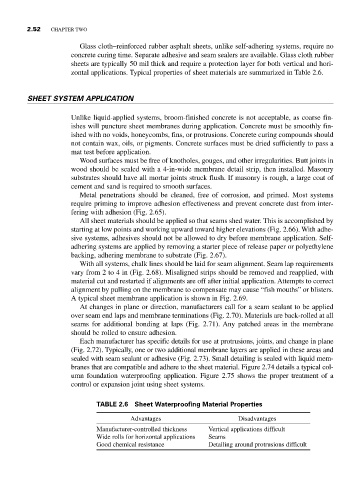

TABLE 2.6 Sheet Waterproofing Material Properties

Advantages Disadvantages

Manufacturer-controlled thickness Vertical applications difficult

Wide rolls for horizontal applications Seams

Good chemical resistance Detailing around protrusions difficult