Page 91 - Construction Waterproofing Handbook

P. 91

2.54 CHAPTER TWO

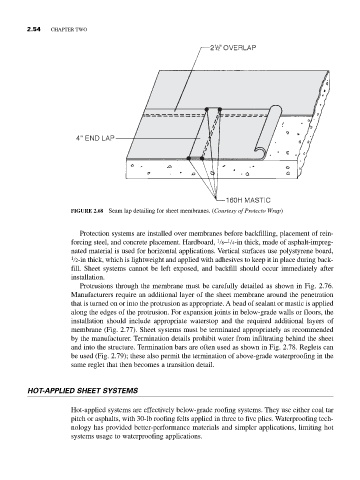

FIGURE 2.68 Seam lap detailing for sheet membranes. (Courtesy of Protecto Wrap)

Protection systems are installed over membranes before backfilling, placement of rein-

1

1

forcing steel, and concrete placement. Hardboard, 8– 4-in thick, made of asphalt-impreg-

nated material is used for horizontal applications. Vertical surfaces use polystyrene board,

1 2-in thick, which is lightweight and applied with adhesives to keep it in place during back-

fill. Sheet systems cannot be left exposed, and backfill should occur immediately after

installation.

Protrusions through the membrane must be carefully detailed as shown in Fig. 2.76.

Manufacturers require an additional layer of the sheet membrane around the penetration

that is turned on or into the protrusion as appropriate. A bead of sealant or mastic is applied

along the edges of the protrusion. For expansion joints in below-grade walls or floors, the

installation should include appropriate waterstop and the required additional layers of

membrane (Fig. 2.77). Sheet systems must be terminated appropriately as recommended

by the manufacturer. Termination details prohibit water from infiltrating behind the sheet

and into the structure. Termination bars are often used as shown in Fig. 2.78. Reglets can

be used (Fig. 2.79); these also permit the termination of above-grade waterproofing in the

same reglet that then becomes a transition detail.

HOT-APPLIED SHEET SYSTEMS

Hot-applied systems are effectively below-grade roofing systems. They use either coal tar

pitch or asphalts, with 30-lb roofing felts applied in three to five plies. Waterproofing tech-

nology has provided better-performance materials and simpler applications, limiting hot

systems usage to waterproofing applications.