Page 334 - Control Theory in Biomedical Engineering

P. 334

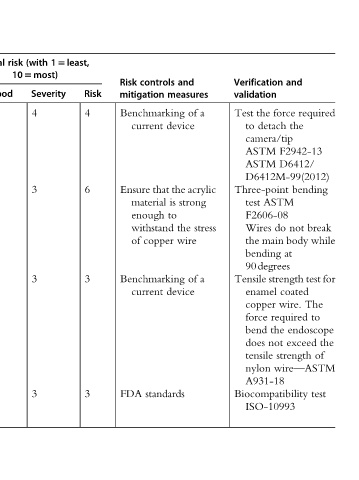

required bending break while for test The to endoscope the of test

and force the F2942-13 D6412/ D6412M-99(2012) ASTM not do body at strength coated wire. required the exceed strength wire—ASTM

Verification validation the Test detach to camera/tip ASTM ASTM Three-point test F2606-08 Wires main the bending 90degrees Tensile enamel copper force bend not does tensile nylon A931-18 Biocompatibility ISO-10993

and measures a of device acrylic the strong is to stress the wire a of device

controls mitigation Benchmarking current that material enough withstand copper Benchmarking current standards

Risk Ensure of FDA

Risk 4 6 3 3

15least,

(with 105most) Severity 4 3 3 3

risk

Initial Likelihood 2 1 1 1

tip a in a in (unable the

flexible is trapped in a patient’s of endoscope trapped patient’s of endoscope trapped patient’s retract endoscope) body response, inflammation

Harm The body Part body Part body to Foreign

failure bending tip principal the tensile the of coated wire biocompatibility material

of the Exceeding of material Exceeding strength enamel copper Inadequate the

Cause Repeated of stress of

analysis tip main

mode mode of endoscope endoscopy of design breakage endoscopy Biocompatibility materials (surface

Failure Failure Breakage during Breakage body Wire during of used