Page 166 - Corrosion Engineering Principles and Practice

P. 166

140 C h a p t e r 5 C o r r o s i o n K i n e t i c s a n d A p p l i c a t i o n s o f E l e c t r o c h e m i s t r y 141

Sealing of Anodic Coatings

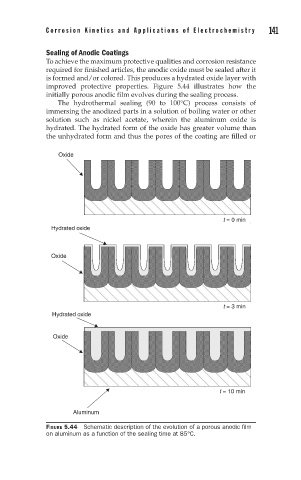

To achieve the maximum protective qualities and corrosion resistance

required for finished articles, the anodic oxide must be sealed after it

is formed and/or colored. This produces a hydrated oxide layer with

improved protective properties. Figure 5.44 illustrates how the

initially porous anodic film evolves during the sealing process.

The hydrothermal sealing (90 to 100°C) process consists of

immersing the anodized parts in a solution of boiling water or other

solution such as nickel acetate, wherein the aluminum oxide is

hydrated. The hydrated form of the oxide has greater volume than

the unhydrated form and thus the pores of the coating are filled or

Oxide

t = 0 min

Hydrated oxide

Oxide

t = 3 min

Hydrated oxide

Oxide

t = 10 min

Aluminum

FIGURE 5.44 Schematic description of the evolution of a porous anodic film

on aluminum as a function of the sealing time at 85°C.