Page 161 - Corrosion Engineering Principles and Practice

P. 161

136 C h a p t e r 5 C o r r o s i o n K i n e t i c s a n d A p p l i c a t i o n s o f E l e c t r o c h e m i s t r y 137

protective anodic film can be damaged and even break down

completely. It follows that although a high current density may be

required to cause passivation (> i ), only a small current density is

cc

required to maintain it, and that in the passive region the corrosion

rate corresponds to the passive current density (i ).

p

Anodic protection possesses unique features. For example, the

applied current is usually equal to the corrosion rate of the protected

system. Thus, anodic protection not only protects but also offers a

direct means for monitoring the corrosion rate of a system. The

main advantages of anodic protection are (1) low current

requirements; (2) large reductions in corrosion rate (typically

10,000-fold or more); and (3) applicability to certain strong, hot

acids and other highly corrosive media. It is important to emphasize

that anodic protection can only be applied to metals and alloys

possessing active-passive characteristics such as titanium, stainless

steels, steel, and nickel-base alloys.

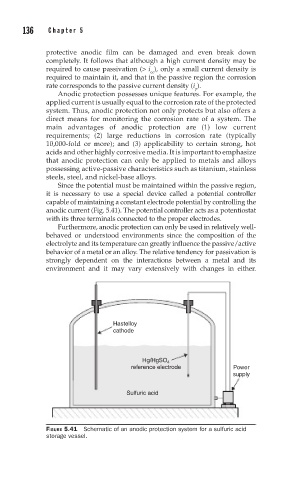

Since the potential must be maintained within the passive region,

it is necessary to use a special device called a potential controller

capable of maintaining a constant electrode potential by controlling the

anodic current (Fig. 5.41). The potential controller acts as a potentiostat

with its three terminals connected to the proper electrodes.

Furthermore, anodic protection can only be used in relatively well-

behaved or understood environments since the composition of the

electrolyte and its temperature can greatly influence the passive/active

behavior of a metal or an alloy. The relative tendency for passivation is

strongly dependent on the interactions between a metal and its

environment and it may vary extensively with changes in either.

Hastelloy

cathode

Hg/HgSO

4

reference electrode Power

supply

Sulfuric acid

FIGURE 5.41 Schematic of an anodic protection system for a sulfuric acid

storage vessel.