Page 293 - Corrosion Engineering Principles and Practice

P. 293

C o r r o s i o n b y W a t e r 267

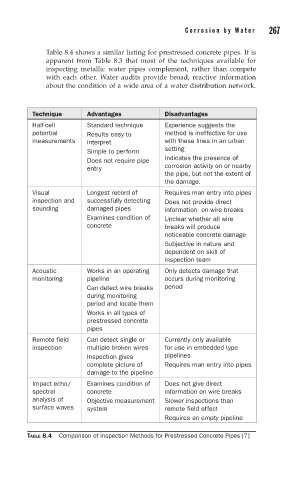

Table 8.4 shows a similar listing for prestressed concrete pipes. It is

apparent from Table 8.3 that most of the techniques available for

inspecting metallic water pipes complement, rather than compete

with each other. Water audits provide broad, reactive information

about the condition of a wide area of a water distribution network.

Technique Advantages Disadvantages

Half-cell Standard technique Experience suggests the

potential Results easy to method is ineffective for use

measurements interpret with these lines in an urban

Simple to perform setting

Does not require pipe Indicates the presence of

entry corrosion activity on or nearby

the pipe, but not the extent of

the damage.

Visual Longest record of Requires man entry into pipes

inspection and successfully detecting Does not provide direct

sounding damaged pipes information on wire breaks

Examines condition of Unclear whether all wire

concrete breaks will produce

noticeable concrete damage

Subjective in nature and

dependent on skill of

inspection team

Acoustic Works in an operating Only detects damage that

monitoring pipeline occurs during monitoring

Can detect wire breaks period

during monitoring

period and locate them

Works in all types of

prestressed concrete

pipes

Remote field Can detect single or Currently only available

inspection multiple broken wires for use in embedded type

Inspection gives pipelines

complete picture of Requires man entry into pipes

damage to the pipeline

Impact echo/ Examines condition of Does not give direct

spectral concrete information on wire breaks

analysis of Objective measurement Slower inspections than

surface waves system remote field effect

Requires an empty pipeline

TABLE 8.4 Comparison of Inspection Methods for Prestressed Concrete Pipes [7]