Page 288 - Corrosion Engineering Principles and Practice

P. 288

262 C h a p t e r 8 C o r r o s i o n b y W a t e r 263

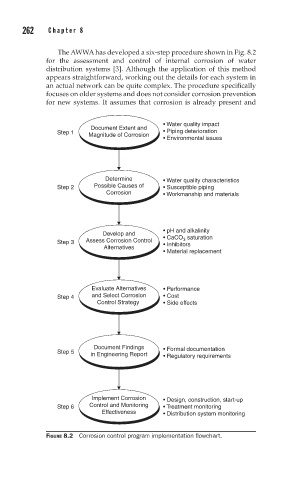

The AWWA has developed a six-step procedure shown in Fig. 8.2

for the assessment and control of internal corrosion of water

distribution systems [3]. Although the application of this method

appears straightforward, working out the details for each system in

an actual network can be quite complex. The procedure specifically

focuses on older systems and does not consider corrosion prevention

for new systems. It assumes that corrosion is already present and

• Water quality impact

Document Extent and

Step 1 Magnitude of Corrosion • Piping deterioration

• Environmental issues

Determine • Water quality characteristics

Step 2 Possible Causes of • Susceptible piping

Corrosion • Workmanship and materials

• pH and alkalinity

Develop and • CaCO saturation

3

Step 3 Assess Corrosion Control • Inhibitors

Alternatives

• Material replacement

Evaluate Alternatives • Performance

Step 4 and Select Corrosion • Cost

Control Strategy • Side effects

Document Findings • Formal documentation

Step 5 in Engineering Report • Regulatory requirements

Implement Corrosion • Design, construction, start-up

Step 6 Control and Monitoring • Treatment monitoring

Effectiveness • Distribution system monitoring

FIGURE 8.2 Corrosion control program implementation flowchart.