Page 45 - Corrosion Engineering Principles and Practice

P. 45

C o r r o s i o n B a s i c s 27

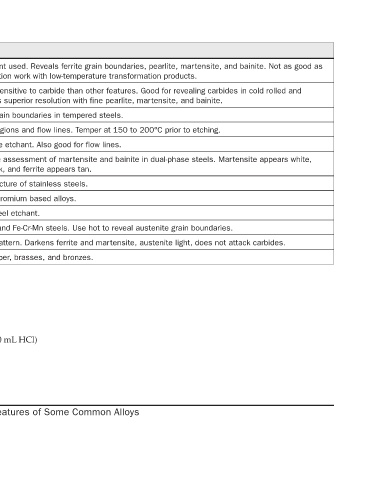

Most common etchant used. Reveals ferrite grain boundaries, pearlite, martensite, and bainite. Not as good as

As above but more sensitive to carbide than other features. Good for revealing carbides in cold rolled and

annealed strip. Gives superior resolution with fine pearlite, martensite, and bainite.

picral for high-resolution work with low-temperature transformation products.

Reveals austenite grain boundaries in tempered steels. Reveals deformed regions and flow lines. Temper at 150 to 200°C prior to etching. Segregation sensitive etchant. Also good for flow lines. Good for quantitative assessment of martensite and bainite in dual-phase steels. Martensite appears white, ba

Comments General stainless steel etchant. Chemical Etchants Used to Reveal the Microscopic Features of Some Common Alloys

Etchant Nital 3% or 5% Picral Brauners reagent Fry’s reagent SASPA LePera’s reagent Aqua regia Glycer regia Acid ferric chloride Vilella’s reagent Kalling’s reagent Acid ferric chloride Acid ferric chloride (10 g ferric chloride, 30 mL HCl, 120 mL water) Aqua regia (3 parts HCl plus 1 part ni

Uses Iron & steel Iron & steel Iron & steel Iron & steel Iron & steel Iron & steel Stainless steels Stainless steels Stainless steels Stainless steels Stainless steels Copper alloys TABLE 2.3

26