Page 468 - Corrosion Engineering Principles and Practice

P. 468

434 C h a p t e r 1 1 M a t e r i a l s S e l e c t i o n , Te s t i n g , a n d D e s i g n C o n s i d e r a t i o n s 435

• Experience

Has the material been used in identical situation?

With what specific results?

If equipment is still in operation, has it been inspected?

Has the material been used in similar situations?

What are the differences in performance between the old and new

situations?

Any pilot-plant experience?

Any plant corrosion-test data?

Have laboratory corrosion tests been run?

Are there any available reports?

TABLE 11.1 (continued)

O

100% H 2

3

4

5

2

1

100% H SO 4 100% HNO 3

2

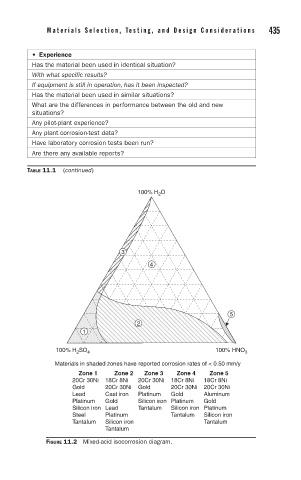

Materials in shaded zones have reported corrosion rates of < 0.50 mm/y

Zone 1 Zone 2 Zone 3 Zone 4 Zone 5

20Cr 30Ni 18Cr 8Ni 20Cr 30Ni 18Cr 8Ni 18Cr 8Ni

Gold 20Cr 30Ni Gold 20Cr 30Ni 20Cr 30Ni

Lead Cast iron Platinum Gold Aluminum

Platinum Gold Silicon iron Platinum Gold

Silicon iron Lead Tantalum Silicon iron Platinum

Steel Platinum Tantalum Silicon iron

Tantalum Silicon iron Tantalum

Tantalum

FIGURE 11.2 Mixed-acid isocorrosion diagram.