Page 472 - Corrosion Engineering Principles and Practice

P. 472

438 C h a p t e r 1 1 M a t e r i a l s S e l e c t i o n , Te s t i n g , a n d D e s i g n C o n s i d e r a t i o n s 439

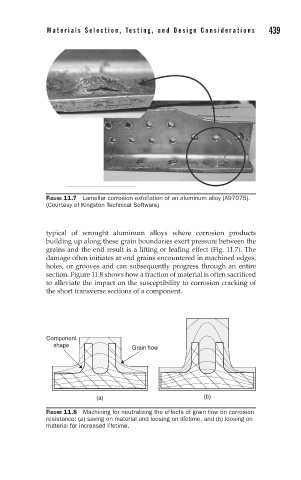

FIGURE 11.7 Lamellar corrosion exfoliation of an aluminum alloy (A97075).

(Courtesy of Kingston Technical Software)

typical of wrought aluminum alloys where corrosion products

building up along these grain boundaries exert pressure between the

grains and the end result is a lifting or leafing effect (Fig. 11.7). The

damage often initiates at end grains encountered in machined edges,

holes, or grooves and can subsequently progress through an entire

section. Figure 11.8 shows how a fraction of material is often sacrificed

to alleviate the impact on the susceptibility to corrosion cracking of

the short transverse sections of a component.

Component

shape Grain flow

(a) (b)

FIGURE 11.8 Machining for neutralizing the effects of grain flow on corrosion

resistance: (a) saving on material and loosing on lifetime, and (b) loosing on

material for increased lifetime.