Page 517 - Corrosion Engineering Principles and Practice

P. 517

484 C h a p t e r 1 2 C o r r o s i o n a s a R i s k 485

Condenser

Reflux

Skip weld

Column wall

External

stiffening

A A ring

Feed Crevice where external

SCC agents can

accumulate

Section A–A

Process-side cracking

External cracking

Tails Both sides cracking

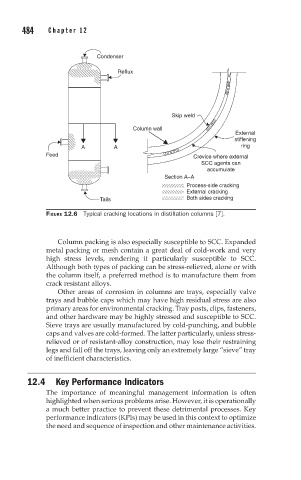

FIGURE 12.6 Typical cracking locations in distillation columns [7].

Column packing is also especially susceptible to SCC. Expanded

metal packing or mesh contain a great deal of cold-work and very

high stress levels, rendering it particularly susceptible to SCC.

Although both types of packing can be stress-relieved, alone or with

the column itself, a preferred method is to manufacture them from

crack resistant alloys.

Other areas of corrosion in columns are trays, especially valve

trays and bubble caps which may have high residual stress are also

primary areas for environmental cracking. Tray posts, clips, fasteners,

and other hardware may be highly stressed and susceptible to SCC.

Sieve trays are usually manufactured by cold-punching, and bubble

caps and valves are cold-formed. The latter particularly, unless stress-

relieved or of resistant-alloy construction, may lose their restraining

legs and fall off the trays, leaving only an extremely large “sieve” tray

of inefficient characteristics.

12.4 Key Performance Indicators

The importance of meaningful management information is often

highlighted when serious problems arise. However, it is operationally

a much better practice to prevent these detrimental processes. Key

performance indicators (KPIs) may be used in this context to optimize

the need and sequence of inspection and other maintenance activities.