Page 605 - Corrosion Engineering Principles and Practice

P. 605

568 C h a p t e r 1 3 C a t h o d i c P r o t e c t i o n 569

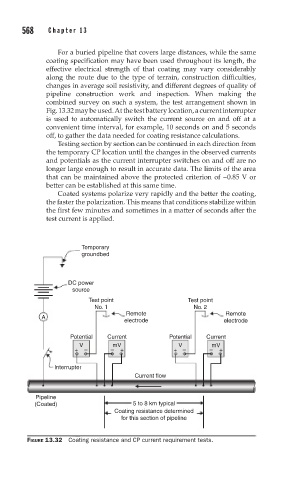

For a buried pipeline that covers large distances, while the same

coating specification may have been used throughout its length, the

effective electrical strength of that coating may vary considerably

along the route due to the type of terrain, construction difficulties,

changes in average soil resistivity, and different degrees of quality of

pipeline construction work and inspection. When making the

combined survey on such a system, the test arrangement shown in

Fig. 13.32 may be used. At the test battery location, a current interrupter

is used to automatically switch the current source on and off at a

convenient time interval, for example, 10 seconds on and 5 seconds

off, to gather the data needed for coating resistance calculations.

Testing section by section can be continued in each direction from

the temporary CP location until the changes in the observed currents

and potentials as the current interrupter switches on and off are no

longer large enough to result in accurate data. The limits of the area

that can be maintained above the protected criterion of −0.85 V or

better can be established at this same time.

Coated systems polarize very rapidly and the better the coating,

the faster the polarization. This means that conditions stabilize within

the first few minutes and sometimes in a matter of seconds after the

test current is applied.

Temporary

groundbed

DC power

source

Test point Test point

No. 1 No. 2

Remote Remote

A

electrode electrode

Potential Current Potential Current

V mV V mV

– – + + – – +

+

Interrupter

Current flow

Pipeline

(Coated) 5 to 8 km typical

Coating resistance determined

for this section of pipeline

FIGURE 13.32 Coating resistance and CP current requirement tests.