Page 609 - Corrosion Engineering Principles and Practice

P. 609

572 C h a p t e r 1 3 C a t h o d i c P r o t e c t i o n 573

GPS satellite GPS satellite

synchronization synchronization

Rectifier

Test station

Reference Copper wire

electrode

Interrupter switch

Voltmeter/logger

Buried pipeline

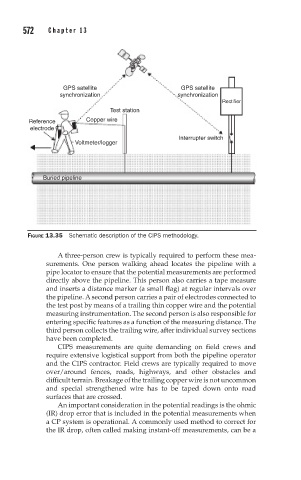

FIGURE 13.35 Schematic description of the CIPS methodology.

A three-person crew is typically required to perform these mea-

surements. One person walking ahead locates the pipeline with a

pipe locator to ensure that the potential measurements are performed

directly above the pipeline. This person also carries a tape measure

and inserts a distance marker (a small flag) at regular intervals over

the pipeline. A second person carries a pair of electrodes connected to

the test post by means of a trailing thin copper wire and the potential

measuring instrumentation. The second person is also responsible for

entering specific features as a function of the measuring distance. The

third person collects the trailing wire, after individual survey sections

have been completed.

CIPS measurements are quite demanding on field crews and

require extensive logistical support from both the pipeline operator

and the CIPS contractor. Field crews are typically required to move

over/around fences, roads, highways, and other obstacles and

difficult terrain. Breakage of the trailing copper wire is not uncommon

and special strengthened wire has to be taped down onto road

surfaces that are crossed.

An important consideration in the potential readings is the ohmic

(IR) drop error that is included in the potential measurements when

a CP system is operational. A commonly used method to correct for

the IR drop, often called making instant-off measurements, can be a