Page 378 - Decision Making Applications in Modern Power Systems

P. 378

340 Decision Making Applications in Modern Power Systems

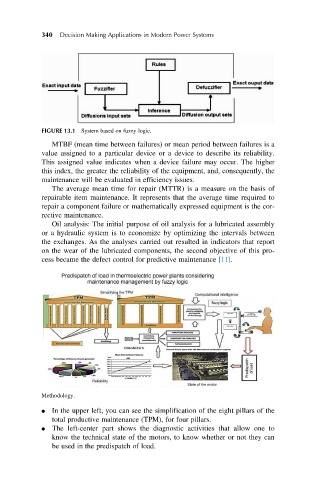

FIGURE 13.1 System based on fuzzy logic.

MTBF (mean time between failures) or mean period between failures is a

value assigned to a particular device or a device to describe its reliability.

This assigned value indicates when a device failure may occur. The higher

this index, the greater the reliability of the equipment, and, consequently, the

maintenance will be evaluated in efficiency issues.

The average mean time for repair (MTTR) is a measure on the basis of

repairable item maintenance. It represents that the average time required to

repair a component failure or mathematically expressed equipment is the cor-

rective maintenance.

Oil analysis: The initial purpose of oil analysis for a lubricated assembly

or a hydraulic system is to economize by optimizing the intervals between

the exchanges. As the analyses carried out resulted in indicators that report

on the wear of the lubricated components, the second objective of this pro-

cess became the defect control for predictive maintenance [11].

Methodology.

In the upper left, you can see the simplification of the eight pillars of the

total productive maintenance (TPM), for four pillars.

The left-center part shows the diagnostic activities that allow one to

know the technical state of the motors, to know whether or not they can

be used in the predispatch of load.