Page 468 - Design and Operation of Heat Exchangers and their Networks

P. 468

Optimal control process of heat exchanger networks 451

Z

Model parameter

modification Z predicted

C ˙

c h h

c

C ˙ h t¢ h t¢ E,h t² E,h t² h

Model predictive

t² h,set controller (1–c )C ˙

Z tar h h t¢ c C c

˙

u 1 u 2 u 3 u 4 t² c

Heat

exchanger

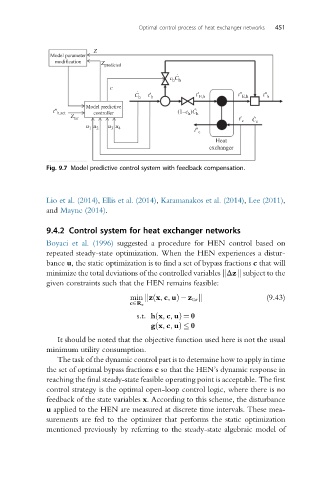

Fig. 9.7 Model predictive control system with feedback compensation.

Lio et al. (2014), Ellis et al. (2014), Karamanakos et al. (2014), Lee (2011),

and Mayne (2014).

9.4.2 Control system for heat exchanger networks

Boyaci et al. (1996) suggested a procedure for HEN control based on

repeated steady-state optimization. When the HEN experiences a distur-

bance u, the static optimization is to find a set of bypass fractions c that will

minimize the total deviations of the controlled variables jjΔzjj subject to the

given constraints such that the HEN remains feasible:

min zx, c, uð Þ z tar k (9.43)

k

c2R c

s:t: hx, c, uÞ ¼ 0

ð

gx, c, uÞ 0

ð

It should be noted that the objective function used here is not the usual

minimum utility consumption.

The task of the dynamic control part is to determine how to apply in time

the set of optimal bypass fractions c so that the HEN’s dynamic response in

reaching the final steady-state feasible operating point is acceptable. The first

control strategy is the optimal open-loop control logic, where there is no

feedback of the state variables x. According to this scheme, the disturbance

u applied to the HEN are measured at discrete time intervals. These mea-

surements are fed to the optimizer that performs the static optimization

mentioned previously by referring to the steady-state algebraic model of