Page 466 - Design and Operation of Heat Exchangers and their Networks

P. 466

Optimal control process of heat exchanger networks 449

Z

DZ

Z tar

C ˙

c h h

c

˙ t¢ t¢ t² t²

C h h E,h E,h h

t² h,set Model predictive ˙

h

controller (1–c )C h

t¢ c C ˙ c

t² c

u 1 u 2 u 3 u 4

Heat

exchanger

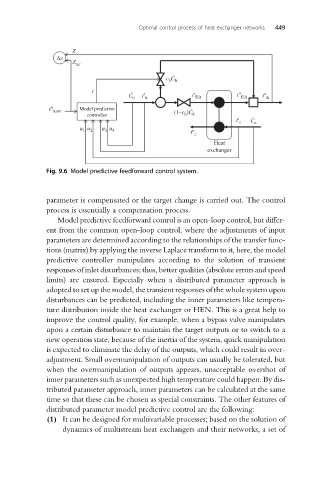

Fig. 9.6 Model predictive feedforward control system.

parameter is compensated or the target change is carried out. The control

process is essentially a compensation process.

Model predictive feedforward control is an open-loop control, but differ-

ent from the common open-loop control, where the adjustments of input

parameters are determined according to the relationships of the transfer func-

tions (matrix) by applying the inverse Laplace transform to it, here, the model

predictive controller manipulates according to the solution of transient

responses of inlet disturbances; thus, better qualities (absolute errors and speed

limits) are ensured. Especially when a distributed parameter approach is

adopted to set up the model, the transient responses of the whole system upon

disturbances can be predicted, including the inner parameters like tempera-

ture distribution inside the heat exchanger or HEN. This is a great help to

improve the control quality, for example, when a bypass valve manipulates

upon a certain disturbance to maintain the target outputs or to switch to a

new operation state, because of the inertia of the system, quick manipulation

is expected to eliminate the delay of the outputs, which could result in over-

adjustment. Small overmanipulation of outputs can usually be tolerated, but

when the overmanipulation of outputs appears, unacceptable overshot of

inner parameters such as unexpected high temperature could happen. By dis-

tributed parameter approach, inner parameters can be calculated at the same

time so that these can be chosen as special constraints. The other features of

distributed parameter model predictive control are the following:

(1) It can be designed for multivariable processes; based on the solution of

dynamics of multistream heat exchangers and their networks, a set of