Page 29 - Design for Environment A Guide to Sustainable Product Development

P. 29

8 Cha pte r O n e

management systems, analogous to the ISO 9000 series for quality

management systems. Many government agencies, notably in the

European Union, were taking aggressive steps to assure that manu-

facturers are responsible for recovery of products and mate rials at

the end of their useful lives. At the same time, there was a growing

voluntary commitment on the part of major manufacturing firms

to assure environmental responsibility for both their internal oper-

ations and their sup pliers. This led to the flourishing of consortia

such as the Global Environmental Manage ment Initiative and the

World Business Council for Sustainable Development, as well as

government-sponsored programs such as ENERGY STAR. All of

these historic changes are described in Chapter 3.

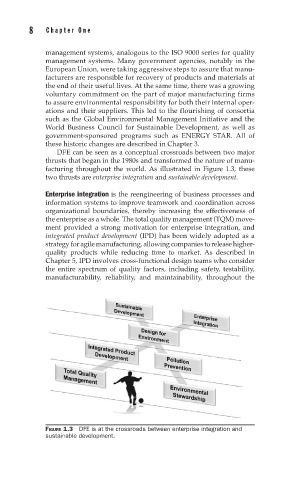

DFE can be seen as a conceptual crossroads between two major

thrusts that began in the 1980s and transform ed the nature of manu-

facturing throughout the world. As illustrated in Figure 1.3, these

two thrusts are enterprise integration and sustainable development.

Enterprise integration is the reengineering of business processes and

information systems to improve teamwork and coordination across

organizational bounda ries, thereby increasing the effectiveness of

the enterprise as a whole. The total quality management (TQM) move-

ment provided a strong motivation for enterprise integration, and

integrated product development (IPD) has been widely adopted as a

stra tegy for agile manufacturing, allowing companies to release higher-

quality products while reducing time to market. As described in

Chapter 5, IPD involves cross-functional design teams who con sider

the entire spectrum of quality factors, including safety, testability,

manufacturability, reliability, and maintainability, through out the

FIGURE 1.3 DFE is at the crossroads between enterprise integration and

sustainable development.