Page 180 - Design for Six Sigma a Roadmap for Product Development

P. 180

Design for Six Sigma Project Algorithm 153

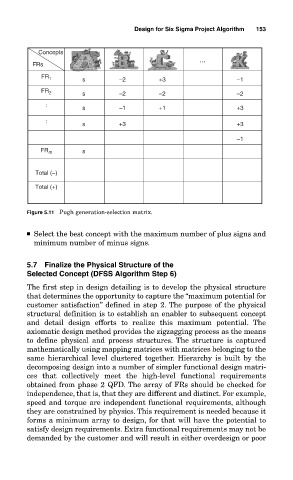

Concepts

…

FRs

FR 1

s –2 +3 –1

FR 2

s –2 –2 –2

:

s –1 +1 +3

:

s +3 +3

–1

s

FR m

Total (–)

Total (+)

Figure 5.11 Pugh generation-selection matrix.

■ Select the best concept with the maximum number of plus signs and

minimum number of minus signs.

5.7 Finalize the Physical Structure of the

Selected Concept (DFSS Algorithm Step 6)

The first step in design detailing is to develop the physical structure

that determines the opportunity to capture the “maximum potential for

customer satisfaction” defined in step 2. The purpose of the physical

structural definition is to establish an enabler to subsequent concept

and detail design efforts to realize this maximum potential. The

axiomatic design method provides the zigzagging process as the means

to define physical and process structures. The structure is captured

mathematically using mapping matrices with matrices belonging to the

same hierarchical level clustered together. Hierarchy is built by the

decomposing design into a number of simpler functional design matri-

ces that collectively meet the high-level functional requirements

obtained from phase 2 QFD. The array of FRs should be checked for

independence, that is, that they are different and distinct. For example,

speed and torque are independent functional requirements, although

they are constrained by physics. This requirement is needed because it

forms a minimum array to design, for that will have the potential to

satisfy design requirements. Extra functional requirements may not be

demanded by the customer and will result in either overdesign or poor