Page 185 - Design for Six Sigma a Roadmap for Product Development

P. 185

158 Chapter Five

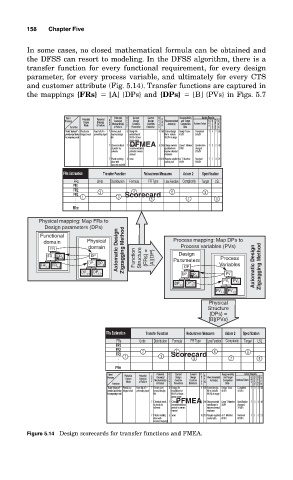

In some cases, no closed mathematical formula can be obtained and

the DFSS can resort to modeling. In the DFSS algorithm, there is a

transfer function for every functional requirement, for every design

parameter, for every process variable, and ultimately for every CTS

and customer attribute (Fig. 5.14). Transfer functions are captured in

the mappings {FRs} [A] {DPs} and {DPs} [B] {PVs} in Figs. 5.7

Item / Potential O Current Current D Responsibility Action Results

Process Potential Potential S Cause(s)/ c Design Design e R. P. Recommended and Target S O D R.

Failure Effect(s) e c Controls Controls t Action(s) Completion Actions Taken e c e

Mode of Failure v Mechanism(s) u e N. v c t P.

Function of Failure r Prevention Detection c Date u e N.

r c

Thumb "keyboard" — Plastic key Keys fall off — 7 Device used 6 Design life 4 168 Extend design Design Team: Completed 7 4 2 56

provides input device hinges break preventing input beyond design established at life to include 4/1/01 5/15/01

for composing e-mail life 99.5% of focus 99.9% of usage

group usage

7 Chemical attack 7 Cleaning DFMEA 5 245 Change material Casey T. Member: Specification 7 3 2 42

of plastic by recommendations specification to 3/1/01 changed:

solvents printed in owners improve chemical 2/15/01

manual resistance

7 Plastic molding 3 none 10 210 Require supplier'sJo T. Member: Received 7 1 3 21

done with control plan 6/1/01 6/15/01

incorrect material

FRs Estimation Transfer Function Robustness Measures Axiom 2 Specification

FRs Units Distribution Formula FR Type Loss Function Complexity Target LSL

FR1

FR2 2 4 4 6 6 8 8

FR3 1 33 Scorecard

: 5 5 7 7 9 9

:

FRm

Physical mapping: Map FRs to

Design parameters (DPs)

Functional

domain Physical Process mapping: Map DPs to

FR domain Axiomatic Design Zigzagging Method Process variables (PVs)

DP Design

FR 1 FR 2 Function Structure {FRs} = [A]{DP} Parameters Process

DP 1 DP 2 Variables

FR 1.1 FR 1.2 DP Axiomatic Design Zigzagging Method

DP 1.1 DP 1.2 PV

DP 1 DP 2

PV 1 PV 2

DP 1.1 DP 1.2

PV 1.1 PV 1.2

Physical

Structure

{DPs} =

[B]{PVs}

FRs Estimation Transfer Function Robustness Measures Axiom 2 Specification

FRs Units Distribution Formula FR Type Loss Function Complexity Target LSL

FR1

FR2 2 4 4 6 6 8 8

FR3 1 33 Scorecard

: 5 5 7 7 9 9

:

FRm

Item / Potential O Current Current D Responsibility Action Results

Process Potential Potential S Cause(s)/ c Design Design e R. P. Recommended and Target S O D R.

Failure Effect(s) e c Controls Controls t Action(s) Completion Actions Taken e c e P.

Mode of Failure v Mechanism(s) u e N. v c t

Function of Failure r Prevention Detection c Date u e N.

r c

Thumb "keyboard" — Plastic key Keys fall off — 7 Device used 6 Design life 4 168 Extend design Design Team: Completed 7 4 2 56

provides input device hinges break preventing input beyond design established at life to include 4/1/01 5/15/01

for composing e-mail life 99.5% of focus 99.9% of usage

group usage

7 Chemical attack 7 Cleaning PFMEA 5 245 Change material Casey T. Member: Specification 7 3 2 42

of plastic by recommendations specification to 3/1/01 changed:

solvents printed in owners improve chemical 2/15/01

manual resistance

7 Plastic molding 3 none 10 210 Require supplier'sJo T. Member: Received 7 1 3 21

done with control plan 6/1/01 6/15/01

incorrect material

Figure 5.14 Design scorecards for transfer functions and FMEA.