Page 389 - Design for Six Sigma a Roadmap for Product Development

P. 389

Design for X 359

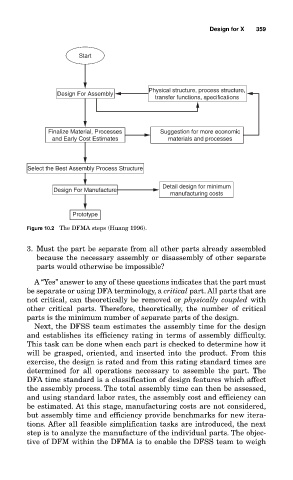

Start

Physical structure, process structure,

Design For Assembly

transfer functions, specifications

Finalize Material, Processes Suggestion for more economic

and Early Cost Estimates materials and processes

Select the Best Assembly Process Structure

Detail design for minimum

Design For Manufacture

manufacturing costs

Prototype

Figure 10.2 The DFMA steps (Huang 1996).

3. Must the part be separate from all other parts already assembled

because the necessary assembly or disassembly of other separate

parts would otherwise be impossible?

A “Yes” answer to any of these questions indicates that the part must

be separate or using DFA terminology, a critical part. All parts that are

not critical, can theoretically be removed or physically coupled with

other critical parts. Therefore, theoretically, the number of critical

parts is the minimum number of separate parts of the design.

Next, the DFSS team estimates the assembly time for the design

and establishes its efficiency rating in terms of assembly difficulty.

This task can be done when each part is checked to determine how it

will be grasped, oriented, and inserted into the product. From this

exercise, the design is rated and from this rating standard times are

determined for all operations necessary to assemble the part. The

DFA time standard is a classification of design features which affect

the assembly process. The total assembly time can then be assessed,

and using standard labor rates, the assembly cost and efficiency can

be estimated. At this stage, manufacturing costs are not considered,

but assembly time and efficiency provide benchmarks for new itera-

tions. After all feasible simplification tasks are introduced, the next

step is to analyze the manufacture of the individual parts. The objec-

tive of DFM within the DFMA is to enable the DFSS team to weigh