Page 396 - Design for Six Sigma a Roadmap for Product Development

P. 396

Design for X 365

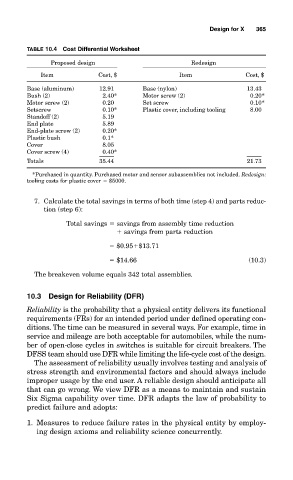

TABLE 10.4 Cost Differential Worksheet

Proposed design Redesign

Item Cost, $ Item Cost, $

Base (aluminum) 12.91 Base (nylon) 13.43

Bush (2) 2.40* Motor screw (2) 0.20*

Motor screw (2) 0.20 Set screw 0.10*

Setscrew 0.10* Plastic cover, including tooling 8.00

Standoff (2) 5.19

End plate 5.89

End-plate screw (2) 0.20*

Plastic bush 0.1*

Cover 8.05

Cover screw (4) 0.40*

Totals 35.44 21.73

*Purchased in quantity. Purchased motor and sensor subassemblies not included. Redesign:

tooling costs for plastic cover $5000.

7. Calculate the total savings in terms of both time (step 4) and parts reduc-

tion (step 6):

Total savings savings from assembly time reduction

savings from parts reduction

$0.95 $13.71

$14.66 (10.3)

The breakeven volume equals 342 total assemblies.

10.3 Design for Reliability (DFR)

Reliability is the probability that a physical entity delivers its functional

requirements (FRs) for an intended period under defined operating con-

ditions. The time can be measured in several ways. For example, time in

service and mileage are both acceptable for automobiles, while the num-

ber of open-close cycles in switches is suitable for circuit breakers. The

DFSS team should use DFR while limiting the life-cycle cost of the design.

The assessment of reliability usually involves testing and analysis of

stress strength and environmental factors and should always include

improper usage by the end user. A reliable design should anticipate all

that can go wrong. We view DFR as a means to maintain and sustain

Six Sigma capability over time. DFR adapts the law of probability to

predict failure and adopts:

1. Measures to reduce failure rates in the physical entity by employ-

ing design axioms and reliability science concurrently.