Page 395 - Design for Six Sigma a Roadmap for Product Development

P. 395

364 Chapter Ten

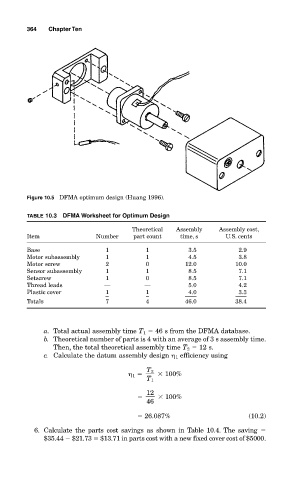

Figure 10.5 DFMA optimum design (Huang 1996).

TABLE 10.3 DFMA Worksheet for Optimum Design

Theoretical Assembly Assembly cost,

Item Number part count time, s U.S. cents

Base 1 1 3.5 2.9

Motor subassembly 1 1 4.5 3.8

Motor screw 2 0 12.0 10.0

Sensor subassembly 1 1 8.5 7.1

Setscrew 1 0 8.5 7.1

Thread leads — — 5.0 4.2

Plastic cover 1 1 4.0 3.3

Totals 7 4 46.0 38.4

a. Total actual assembly time T 1 46 s from the DFMA database.

b. Theoretical number of parts is 4 with an average of 3 s assembly time.

Then, the total theoretical assembly time T 2 12 s.

c. Calculate the datum assembly design 1 efficiency using

T 2

1

100%

T 1

12

100%

46

26.087% (10.2)

6. Calculate the parts cost savings as shown in Table 10.4. The saving

$35.44 $21.73 $13.71 in parts cost with a new fixed cover cost of $5000.