Page 415 - Design for Six Sigma a Roadmap for Product Development

P. 415

382 Chapter Ten

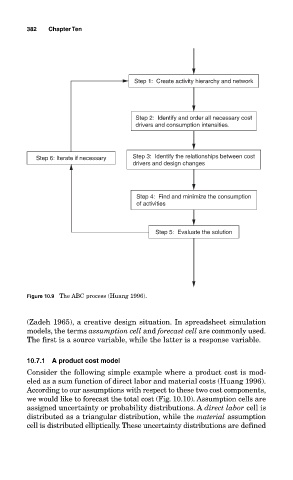

Step 1: Create activity hierarchy and network

Step 2: Identify and order all necessary cost

drivers and consumption intensities.

Step 6: Iterate if necessary Step 3: Identify the relationships between cost

drivers and design changes

Step 4: Find and minimize the consumption

of activities

Step 5: Evaluate the solution

Figure 10.9 The ABC process (Huang 1996).

(Zadeh 1965), a creative design situation. In spreadsheet simulation

models, the terms assumption cell and forecast cell are commonly used.

The first is a source variable, while the latter is a response variable.

10.7.1 A product cost model

Consider the following simple example where a product cost is mod-

eled as a sum function of direct labor and material costs (Huang 1996).

According to our assumptions with respect to these two cost components,

we would like to forecast the total cost (Fig. 10.10). Assumption cells are

assigned uncertainty or probability distributions. A direct labor cell is

distributed as a triangular distribution, while the material assumption

cell is distributed elliptically. These uncertainty distributions are defined