Page 416 - Design for Six Sigma a Roadmap for Product Development

P. 416

Design for X 383

as the DFSS team find appropriate for various reasons; however, we

found these assignments accurate in many applications:

1. Activity: machine cycle time

■ Constant for CNC machines

■ Uniform with parameters (min, max)

■ Triangular with parameters (min, mode, max)

*

2. Activity: conveyor [also automated guided vehicle (AGV)] speed

■ Constant since little variation of actual conveyor speeds

■ Uniform with parameters (min, max)

3. Activity: travel time of AGV, forklift truck, etc.

■ Constant with fixed speed and distance as well as little blockage

■ Triangular with parameters (min, mode, max)

■ Lognormal with parameters (mean, )

†

4. Activity: percent down [when repair time and/or time to (between)

failure(s) is (are) unknown]

■ Must assume distributions (see activities 5 and 6, below) for TTR

and TTF (or TBF) and parameters for one or the other. (We need

both distributions, but only one set of parameters.)

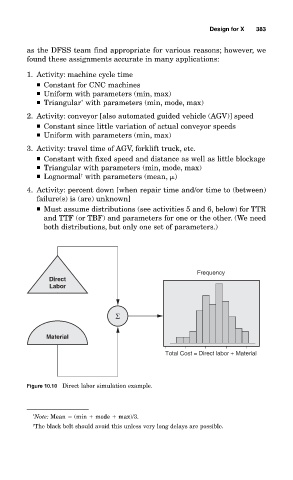

Frequency

Direct

Labor

Σ

Material

Total Cost = Direct labor + Material

Figure 10.10 Direct labor simulation example.

* Note: Mean (min mode max)/3.

† The black belt should avoid this unless very long delays are possible.