Page 596 - Design for Six Sigma a Roadmap for Product Development

P. 596

552 Chapter Fifteen

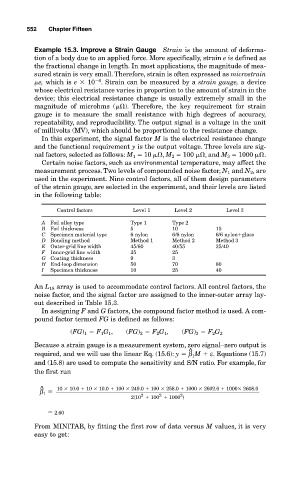

Example 15.3. Improve a Strain Gauge Strain is the amount of deforma-

tion of a body due to an applied force. More specifically, strain e is defined as

the fractional change in length. In most applications, the magnitude of mea-

sured strain is very small. Therefore, strain is often expressed as microstrain

6

e, which is e

10 . Strain can be measured by a strain gauge, a device

whose electrical resistance varies in proportion to the amount of strain in the

device; this electrical resistance change is usually extremely small in the

magnitude of microhms ( ). Therefore, the key requirement for strain

gauge is to measure the small resistance with high degrees of accuracy,

repeatability, and reproducibility. The output signal is a voltage in the unit

of millivolts (MV), which should be proportional to the resistance change.

In this experiment, the signal factor M is the electrical resistance change

and the functional requirement y is the output voltage. Three levels are sig-

nal factors, selected as follows: M 1 10 , M 2 100 , and M 3 1000 .

Certain noise factors, such as environmental temperature, may affect the

measurement process. Two levels of compounded noise factor, N 1 and N 2 , are

used in the experiment. Nine control factors, all of them design parameters

of the strain gauge, are selected in the experiment, and their levels are listed

in the following table:

Control factors Level 1 Level 2 Level 3

A Foil alloy type Type 1 Type 2

B Foil thickness 5 10 15

C Specimen material type 6 nylon 6/6 nylon 6/6 nylon glass

D Bonding method Method 1 Method 2 Method 3

E Outer-grid line width 45/60 40/55 35/40

F Inner-grid line width 35 25

G Coating thickness 9 3

H End-loop dimension 50 70 80

I Specimen thickness 10 25 40

An L 18 array is used to accommodate control factors. All control factors, the

noise factor, and the signal factor are assigned to the inner-outer array lay-

out described in Table 15.3.

In assigning F and G factors, the compound factor method is used. A com-

pound factor termed FG is defined as follows:

(FG) 1 F 1 G 1 , (FG) 2 F 2 G 1 , (FG) 3 F 2 G 2

Because a strain gauge is a measurement system, zero signal–zero output is

^

required, and we will use the linear Eq. (15.6): y β 1 M ε. Equations (15.7)

and (15.8) are used to compute the sensitivity and S/N ratio. For example, for

the first run

^ 10

10.0 10

10.0 100

249.0 100

258.0 1000

2602.0 1000

2608.0

β 1

2

2

2

2(10 100 1000 )

2.60

From MINITAB, by fitting the first row of data versus M values, it is very

easy to get: