Page 611 - Design for Six Sigma a Roadmap for Product Development

P. 611

Design Optimization: Advanced Taguchi Robust Parameter Design 565

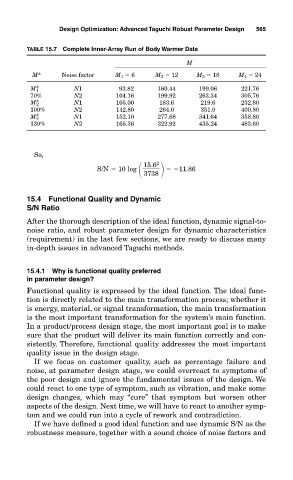

TABLE 15.7 Complete Inner-Array Run of Body Warmer Data

M

M* Noise factor M 1 6 M 2 12 M 3 18 M 4 24

M* 1 N1 93.82 160.44 199.06 221.76

70% N2 104.16 199.92 263.34 305.76

M* 2 N1 105.00 183.6 219.6 232.80

100% N2 142.80 264.0 351.0 400.80

M* 3 N1 152.10 277.68 341.64 358.80

130% N2 165.36 322.92 435.24 483.60

So,

15.6 2

S/N 10 log 11.86

3738

15.4 Functional Quality and Dynamic

S/N Ratio

After the thorough description of the ideal function, dynamic signal-to-

noise ratio, and robust parameter design for dynamic characteristics

(requirement) in the last few sections, we are ready to discuss many

in-depth issues in advanced Taguchi methods.

15.4.1 Why is functional quality preferred

in parameter design?

Functional quality is expressed by the ideal function. The ideal func-

tion is directly related to the main transformation process; whether it

is energy, material, or signal transformation, the main transformation

is the most important transformation for the system’s main function.

In a product/process design stage, the most important goal is to make

sure that the product will deliver its main function correctly and con-

sistently. Therefore, functional quality addresses the most important

quality issue in the design stage.

If we focus on customer quality, such as percentage failure and

noise, at parameter design stage, we could overreact to symptoms of

the poor design and ignore the fundamental issues of the design. We

could react to one type of symptom, such as vibration, and make some

design changes, which may “cure” that symptom but worsen other

aspects of the design. Next time, we will have to react to another symp-

tom and we could run into a cycle of rework and contradiction.

If we have defined a good ideal function and use dynamic S/N as the

robustness measure, together with a sound choice of noise factors and