Page 340 - Design for Six Sigma for Service (Six SIGMA Operational Methods)

P. 340

300 Chapter Ten

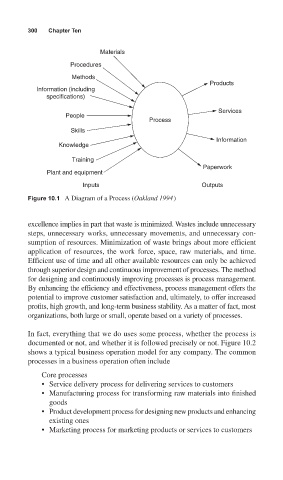

Materials

Procedures

Methods

Products

Information (including

specifications)

Services

People

Process

Skills

Information

Knowledge

Training

Paperwork

Plant and equipment

Inputs Outputs

Figure 10.1 A Diagram of a Process (Oakland 1994)

excellence implies in part that waste is minimized. Wastes include unnecessary

steps, unnecessary works, unnecessary movements, and unnecessary con-

sumption of resources. Minimization of waste brings about more efficient

application of resources, the work force, space, raw materials, and time.

Efficient use of time and all other available resources can only be achieved

through superior design and continuous improvement of processes. The method

for designing and continuously improving processes is process management.

By enhancing the efficiency and effectiveness, process management offers the

potential to improve customer satisfaction and, ultimately, to offer increased

profits, high growth, and long-term business stability. As a matter of fact, most

organizations, both large or small, operate based on a variety of processes.

In fact, everything that we do uses some process, whether the process is

documented or not, and whether it is followed precisely or not. Figure 10.2

shows a typical business operation model for any company. The common

processes in a business operation often include

Core processes

• Service delivery process for delivering services to customers

• Manufacturing process for transforming raw materials into finished

goods

• Product development process for designing new products and enhancing

existing ones

• Marketing process for marketing products or services to customers