Page 111 - Design of Reinforced Masonry Structures

P. 111

MATERIALS OF MASONRY CONSTRUCTION 3.5

in the laboratory are maintained in the field. Water added in the field as determined by the

mason for both methods of specifying mortar. Either proportions or properties specification,

but not both, should be specified. If the project specifications do not indicate which of the

two specifications is to be followed, the properties specifications govern, unless that data

qualifying the mortar under the property specification are presented to and accepted by the

specifier. Excessive amounts of pigments used to achieve mortar color may reduce both the

compressive and bond strength of the masonry. As pointed out earlier, admixtures containing

excessive amount of chloride ions are detrimental to items (reinforcing steel, joint reinforce-

ment, wall ties, metal connectors and inserts, etc.) placed in mortar or grout.

3.2.5 Selection of the Right Mortar Type

There is no single mortar mix that is uniquely suitable for all applications. No one mortar type

rates the highest in all areas of applications. No single mortar property defines mortar qual-

ity. Therefore, it is very important to understand the selection of the right type of mortar as it

influences both the construction process and the quality of finished product. ASTM Standard

specifications provide a means for specifications to identify acceptable materials and products

without limiting those items to specific brands of manufacturers. Project specifications should

reference ASTM C270-05a, the Standard Specification for Mortar of Unit Masonry.

The different mortar types are used for a variety of masonry applications. Type N mortar

is a general-purpose mortar that provides good workability and serviceability. It is com-

monly used for interior walls, above-grade exterior walls under normal conditions, and

for veneers. Type S mortar is used for structural load-bearing applications and for exterior

applications for at or below grade. In addition, it also provides increased resistance to

freeze-thaw deterioration. Type M is high-strength mortar, which may be considered for

load-bearing or severe free-thaw applications. Type O is a low-strength mortar that is some-

times used for interior masonry or pointing. Special attention should be given when severe

exposure conditions are expected. Type O mortar should not be used in saturated freezing

conditions. Table 3.1 (adapted from ASTM C270-05a) provided guidelines for selecting

mortar unreinforced (plain) masonry.

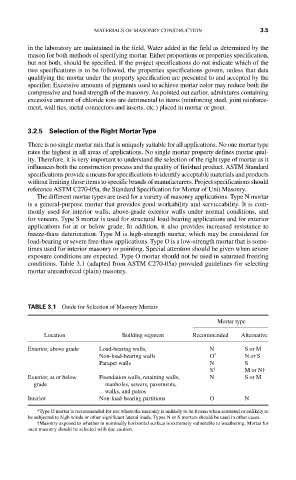

TABLE 3.1 Guide for Selection of Masonry Mortars

Mortar type

Location Building segment Recommended Alternative

Exterior, above grade Load-bearing walls, N S or M

Non-load-bearing walls O * N or S

Parapet walls N S

S † M or N†

Exterior, at or below Foundation walls, retaining walls, N S or M

grade manholes, sewers, pavements,

walks, and patios

Interior Non-load-bearing partitions O N

*Type O mortar is recommended for use where the masonry is unlikely to be frozen when saturated or unlikely to

be subjected to high winds or other significant lateral loads. Types N or S mortars should be used in other cases.

†Masonry exposed to whether in nominally horizontal surface is extremely vulnerable to weathering. Mortar for

such masonry should be selected with due caution.