Page 114 - Design of Reinforced Masonry Structures

P. 114

3.8 CHAPTER THREE

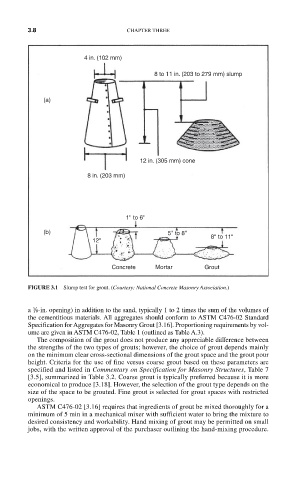

4 in. (102 mm)

8 to 11 in. (203 to 279 mm) slump

(a)

12 in. (305 mm) cone

8 in. (203 mm)

1'' to 6''

(b) 5'' to 8''

8'' to 11''

12''

Concrete Mortar Grout

FIGURE 3.1 Slump test for grout. (Courtesy: National Concrete Masonry Association.)

3

a / 8-in. opening) in addition to the sand, typically 1 to 2 times the sum of the volumes of

the cementitious materials. All aggregates should conform to ASTM C476-02 Standard

Specification for Aggregates for Masonry Grout [3.16]. Proportioning requirements by vol-

ume are given in ASTM C476-02, Table 1 (outlined as Table A.3).

The composition of the grout does not produce any appreciable difference between

the strengths of the two types of grouts; however, the choice of grout depends mainly

on the minimum clear cross-sectional dimensions of the grout space and the grout pour

height. Criteria for the use of fine versus coarse grout based on these parameters are

specified and listed in Commentary on Specification for Masonry Structures, Table 7

[3.5], summarized in Table 3.2. Coarse grout is typically preferred because it is more

economical to produce [3.18]. However, the selection of the grout type depends on the

size of the space to be grouted. Fine grout is selected for grout spaces with restricted

openings.

ASTM C476-02 [3.16] requires that ingredients of grout be mixed thoroughly for a

minimum of 5 min in a mechanical mixer with sufficient water to bring the mixture to

desired consistency and workability. Hand mixing of grout may be permitted on small

jobs, with the written approval of the purchaser outlining the hand-mixing procedure.