Page 116 - Design of Reinforced Masonry Structures

P. 116

3.10 CHAPTER THREE

Cover units with

absorptive paper

towelling

Grout test prism,

1 1

3 × 3 × 7 in.

2 2

Tape

3 1 × 3 1 × 5 -in.

2 2 8

wood pallet Front block removed for clarity

(nonabsorptive)

Mold with four 8 × 8 × 16-in. blocks

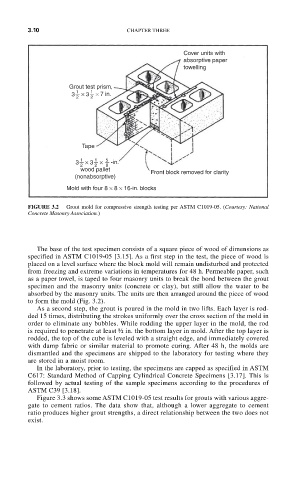

FIGURE 3.2 Grout mold for compressive strength testing per ASTM C1019-05. (Courtesy: National

Concrete Masonry Association.)

The base of the test specimen consists of a square piece of wood of dimensions as

specified in ASTM C1019-05 [3.15]. As a first step in the test, the piece of wood is

placed on a level surface where the block mold will remain undisturbed and protected

from freezing and extreme variations in temperatures for 48 h. Permeable paper, such

as a paper towel, is taped to four masonry units to break the bond between the grout

specimen and the masonry units (concrete or clay), but still allow the water to be

absorbed by the masonry units. The units are then arranged around the piece of wood

to form the mold (Fig. 3.2).

As a second step, the grout is poured in the mold in two lifts. Each layer is rod-

ded 15 times, distributing the strokes uniformly over the cross section of the mold in

order to eliminate any bubbles. While rodding the upper layer in the mold, the rod

is required to penetrate at least ½ in. the bottom layer in mold. After the top layer is

rodded, the top of the cube is leveled with a straight edge, and immediately covered

with damp fabric or similar material to promote curing. After 48 h, the molds are

dismantled and the specimens are shipped to the laboratory for testing where they

are stored in a moist room.

In the laboratory, prior to testing, the specimens are capped as specified in ASTM

C617: Standard Method of Capping Cylindrical Concrete Specimens [3.17]. This is

followed by actual testing of the sample specimens according to the procedures of

ASTM C39 [3.18].

Figure 3.3 shows some ASTM C1019-05 test results for grouts with various aggre-

gate to cement ratios. The data show that, although a lower aggregate to cement

ratio produces higher grout strengths, a direct relationship between the two does not

exist.