Page 124 - Design of Reinforced Masonry Structures

P. 124

3.18 CHAPTER THREE

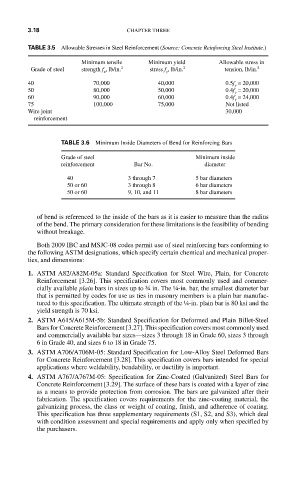

TABLE 3.5 Allowable Stresses in Steel Reinforcement (Source: Concrete Reinforcing Steel Institute.)

Minimum tensile Minimum yield Allowable stress in

2

Grade of steel strength f u , lb/in. 2 stress f y , lb/in. tension, lb/in. 2

40 70,000 40,000 0.5f y = 20,000

50 80,000 50,000 0.4f = 20,000

y

60 90,000 60,000 0.4f = 24,000

y

75 100,000 75,000 Not listed

Wire joint 30,000

reinforcement

TABLE 3.6 Minimum Inside Diameters of Bend for Reinforcing Bars

Grade of steel Minimum inside

reinforcement Bar No. diameter

40 3 through 7 5 bar diameters

50 or 60 3 through 8 6 bar diameters

50 or 60 9, 10, and 11 8 bar diameters

of bend is referenced to the inside of the bars as it is easier to measure than the radius

of the bend. The primary consideration for these limitations is the feasibility of bending

without breakage.

Both 2009 IBC and MSJC-08 codes permit use of steel reinforcing bars conforming to

the following ASTM designations, which specify certain chemical and mechanical proper-

ties, and dimensions:

1. ASTM A82/A82M-05a: Standard Specification for Steel Wire, Plain, for Concrete

Reinforcement [3.26]. This specification covers most commonly used and commer-

cially available plain bars in sizes up to ¾ in. The ¼-in. bar, the smallest diameter bar

that is permitted by codes for use as ties in masonry members is a plain bar manufac-

tured to this specification. The ultimate strength of the ¼-in. plain bar is 80 ksi and the

yield strength is 70 ksi.

2. ASTM A615/A615M-5b: Standard Specification for Deformed and Plain Billet-Steel

Bars for Concrete Reinforcement [3.27]. This specification covers most commonly used

and commercially available bar sizes—sizes 3 through 18 in Grade 60, sizes 3 through

6 in Grade 40, and sizes 6 to 18 in Grade 75.

3. ASTM A706/A706M-05: Standard Specification for Low-Alloy Steel Deformed Bars

for Concrete Reinforcement [3.28]. This specification covers bars intended for special

applications where weldability, bendability, or ductility is important.

4. ASTM A767/A767M-05: Specification for Zinc-Coated (Galvanized) Steel Bars for

Concrete Reinforcement [3.29]. The surface of these bars is coated with a layer of zinc

as a means to provide protection from corrosion. The bars are galvanized after their

fabrication. The specification covers requirements for the zinc-coating material, the

galvanizing process, the class or weight of coating, finish, and adherence of coating.

This specification has three supplementary requirements (S1, S2, and S3), which deal

with condition assessment and special requirements and apply only when specified by

the purchasers.