Page 199 - Design of Simple and Robust Process Plants

P. 199

184 Chapter 5 Process Simplification and Intensification Techniques

. install side reboiler with superheated steam reboiler in the bottom;

. install gas turbine in front of fired reboiler furnace; and

. install air pre-heater and combine its thermal load with other high tempera-

ture process demands.

Other applications will require equally careful study. The need of a furnace is not

always avoidable, but it is worth exploring the options. For example, it may be bene-

ficial to know about the initiation of an exothermal reaction say 300 C (see

Fig 4.38). By taking advantage of the superheat in steam, it may be possible to start-

up such a reactor; after the reactor starts the reactor system can be self supporting

and a furnace can be avoided.

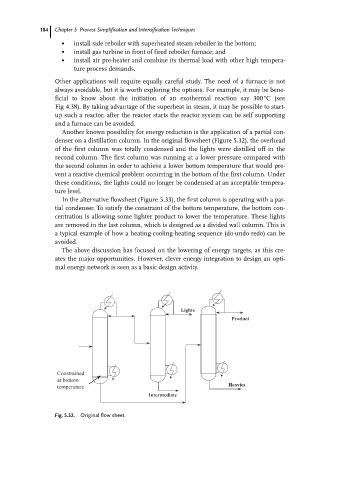

Another known possibility for energy reduction is the application of a partial con-

denser on a distillation column. In the original flowsheet (Figure 5.32), the overhead

of the first column was totally condensed and the lights were distilled off in the

second column. The first column was running at a lower pressure compared with

the second column in order to achieve a lower bottom temperature that would pre-

vent a reactive chemical problem occurring in the bottom of the first column. Under

these conditions, the lights could no longer be condensed at an acceptable tempera-

ture level.

In the alternative flowsheet (Figure 5.33), the first column is operating with a par-

tial condenser. To satisfy the constraint of the bottom temperature, the bottom con-

centration is allowing some lighter product to lower the temperature. These lights

are removed in the last column, which is designed as a divided wall column. This is

a typical example of how a heating-cooling-heating sequence (do-undo-redo) can be

avoided.

The above discussion has focused on the lowering of energy targets, as this cre-

ates the major opportunities. However, clever energy integration to design an opti-

mal energy network is seen as a basic design activity.

Lights

Product

Constrained

at bottom

Heavies

temperature

Intermediate

Fig. 5.32. Original flow sheet.