Page 201 - Design of Simple and Robust Process Plants

P. 201

186 Chapter 5 Process Simplification and Intensification Techniques

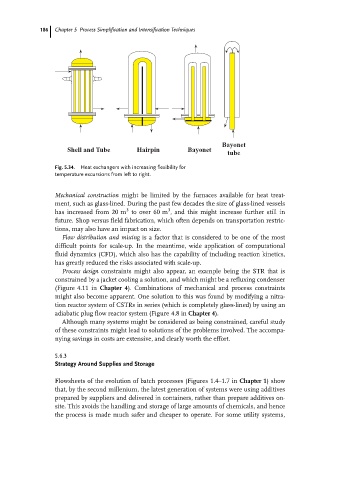

Bayonet

Shell and Tube Hairpin Bayonet

tube

Fig. 5.34. Heat exchangers with increasing flexibility for

temperature excursions from left to right.

Mechanical construction might be limited by the furnaces available for heat treat-

ment, such as glass-lined. During the past few decades the size of glass-lined vessels

3

3

has increased from 20 m to over 60 m , and this might increase further still in

future. Shop versus field fabrication, which often depends on transportation restric-

tions, may also have an impact on size.

Flow distribution and mixing is a factor that is considered to be one of the most

difficult points for scale-up. In the meantime, wide application of computational

fluid dynamics (CFD), which also has the capability of including reaction kinetics,

has greatly reduced the risks associated with scale-up.

Process design constraints might also appear, an example being the STR that is

constrained by a jacket cooling a solution, and which might be a refluxing condenser

(Figure 4.11 in Chapter 4). Combinations of mechanical and process constraints

might also become apparent. One solution to this was found by modifying a nitra-

tion reactor system of CSTRs in series (which is completely glass-lined) by using an

adiabatic plug flow reactor system (Figure 4.8 in Chapter 4).

Although many systems might be considered as being constrained, careful study

of these constraints might lead to solutions of the problems involved. The accompa-

nying savings in costs are extensive, and clearly worth the effort.

5.6.3

Strategy Around Supplies and Storage

Flowsheets of the evolution of batch processes (Figures 1.4±1.7 in Chapter 1) show

that, by the second millenium, the latest generation of systems were using additives

prepared by suppliers and delivered in containers, rather than prepare additives on-

site. This avoids the handling and storage of large amounts of chemicals, and hence

the process is made much safer and cheaper to operate. For some utility systems,