Page 200 - Design of Simple and Robust Process Plants

P. 200

5.6 Overall Process Simplification 185

Partial

condenser Vapor

Intermediate

Lights

Product

Feed

Heavies

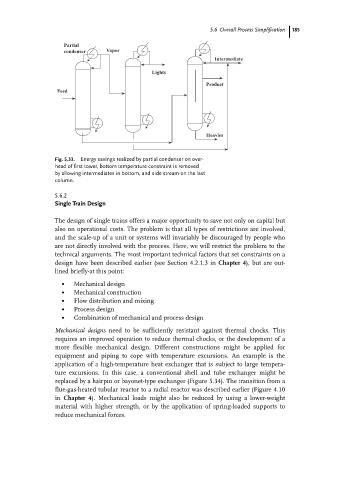

Fig. 5.33. Energy savings realized by partial condenser on over-

head of first tower, bottom temperature constraint is removed

by allowing intermediates in bottom, and side stream on the last

column.

5.6.2

Single Train Design

The design of single trains offers a major opportunity to save not only on capital but

also on operational costs. The problem is that all types of restrictions are involved,

and the scale-up of a unit or systems will invariably be discouraged by people who

are not directly involved with the process. Here, we will restrict the problem to the

technical arguments. The most important technical factors that set constraints on a

design have been described earlier (see Section 4.2.1.3 in Chapter 4), but are out-

lined briefly-at this point:

. Mechanical design

. Mechanical construction

. Flow distribution and mixing

. Process design

. Combination of mechanical and process design

Mechanical designs need to be sufficiently resistant against thermal chocks. This

requires an improved operation to reduce thermal chocks, or the development of a

more flexible mechanical design. Different constructions might be applied for

equipment and piping to cope with temperature excursions. An example is the

application of a high-temperature heat exchanger that is subject to large tempera-

ture excursions. In this case, a conventional shell and tube exchanger might be

replaced by a hairpin or bayonet-type exchanger (Figure 5.34). The transition from a

flue-gas-heated tubular reactor to a radial reactor was described earlier (Figure 4.10

in Chapter 4). Mechanical loads might also be reduced by using a lower-weight

material with higher strength, or by the application of spring-loaded supports to

reduce mechanical forces.