Page 272 - Drilling Technology in Nontechnical Language

P. 272

Chapter 11 – WELL CONTROL 263

Below the rams are pipes that come out to the side. These are called

side outlets and are used to allow flow out of or into the annulus during

well killing operations.

The side outlets have different names. One side connects to the

standpipe manifold to allow flow to be directed into the annulus. This is

called the kill line. The opposite side connects to a manifold of valves and

chokes. This is called the choke line, and its purpose is to allow flow out of

the annulus to be controlled. Chokes are described below.

Once the driller detects that a kick is in progress, one of the BOP stack

preventer units will be closed to seal the annulus of the well.

The pressure at the top of the well (inside the drillpipe and at the top of

the annulus) will be recorded. Once the pressures are steady, the formation

pore pressure (due to hydrostatic and surface pressure) can be calculated.

A plan can then be formulated to kill the well.

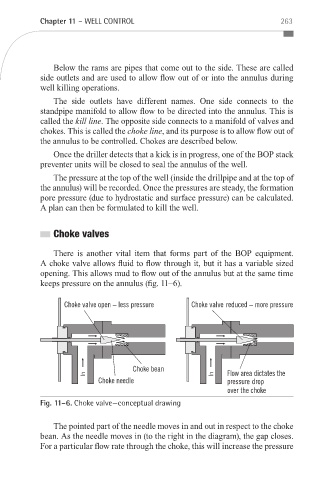

Choke valves

There is another vital item that forms part of the BOP equipment.

A choke valve allows fluid to flow through it, but it has a variable sized

opening. This allows mud to flow out of the annulus but at the same time

keeps pressure on the annulus (fig. 11–6).

Fig. 11–6. Choke valve—conceptual drawing

The pointed part of the needle moves in and out in respect to the choke

bean. As the needle moves in (to the right in the diagram), the gap closes.

For a particular flow rate through the choke, this will increase the pressure

_Devereux_Book.indb 263 1/16/12 2:12 PM