Page 433 - Dust Explosions in the Process Industries

P. 433

400 Dust Explosions in the Process Industries

The induction time to ignition is an important parameter from the point of view of

industrial safety, because it specifies a time frame within which precautions may be

taken to prevent self-ignition. This, in particular, applies to large volumes at compara-

tively low ambient temperatures, for which the induction times may be very long.

The finite elementcomputer simulation approach offers a possibility for analyzing self-

ignition hazards in a wide range of other geometrical configurations than cylinders. Dik

(1987) proposed the use of the thermal impedance method for numerical prediction of

critical conditions for self-ignition for various boundary conditions.

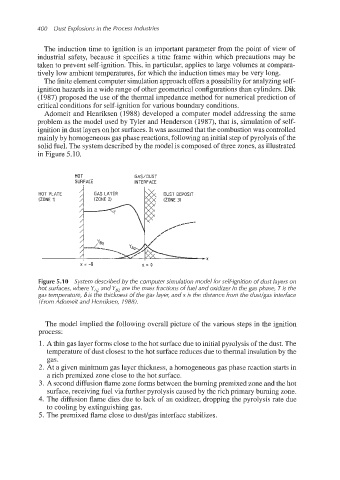

Adomeit and Henriksen (1988) developed a computer model addressing the same

problem as the model used by Tyler and Henderson (1987), that is, simulation of self-

ignition in dust layers on hot surfaces. It was assumed that the combustion was controlled

mainly by homogeneous gas phase reactions, following an initial step of pyrolysis of the

solid fuel. The system described by the model is composed of three zones, as illustrated

in Figure 5.10.

HOT GAS/DUST

SURFACE INTERFACE

DUST DEPOSIT

X

x = -6 x=o

Figure 5.1 0 System described by the computer simulation model for self-ignition of dust layers on

hot surfaces, where Y,, and Y,, are the mass fractions of fuel and oxidizer in the gas phase, T is the

gas temperature, 6 is the thickness of the gas layer,and x is the distance from the dudgas interface

(FromAdomeit and Henriksen, 1988).

The model implied the following overall picture of the various steps in the ignition

process:

1. A thin gas layer forms close to the hot surface due to initial pyrolysis of the dust. The

temperature of dust closest to the hot surfacereduces due to thermal insulationby the

gas.

2. At a given minimum gas layer thickness, a homogeneous gas phase reaction starts in

a rich premixed zone close to the hot surface.

3. A second diffusion flame zone forms between the burning premixed zone and the hot

surface, receiving fuel via further pyrolysis caused by the rich primary burning zone.

4. The diffusion flame dies due to lack of an oxidizer, dropping the pyrolysis rate due

to cooling by extinguishing gas.

5. The premixed flame close to dust/gas interface stabilizes.