Page 547 - Dust Explosions in the Process Industries

P. 547

5 14 Dust Explosions in the Process Industries

40 mrr7 OUST SAMPLE UPPER PLUNGER, 10 mm 0

CENTERING RING

CENTERING PLATE

ANVIL

FAIN

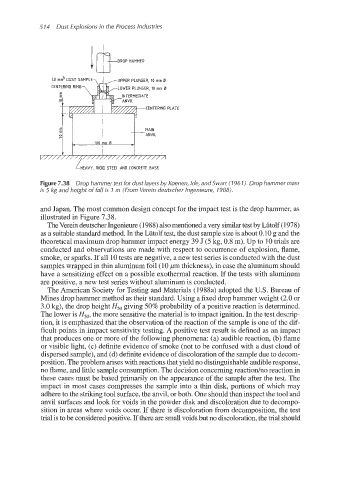

Figure 7.38 Drop hammer test for dust layers by Koenen, Ide, and Swart (196 1). Drop hammer mass

is 5 kg and height of fall is 1 rn (From Verein deutscher Ingenieure, 1988).

and Japan. The most common design concept for the impact test is the drop hammer, as

illustrated in Figure 7.38.

TheVerein deutscherIngenieure(1988) also mentioned a very similartest by Lutolf (1978)

as a suitable standard method. In the Liitolf test, the dust sample sizeis about 0.10 g and the

theoretical maximum drop hammer impact energy 39 J (5 kg, 0.8 m). Up to 10 trials are

conducted and observations are made with respect to occurrence of explosion, flame,

smoke, or sparks. If all 10 tests are negative, a new test series is conducted with the dust

samples wrapped in thin aluminum foil (10 pm thickness), in case the aluminum should

have a sensitizing effect on a possible exothermal reaction. If the tests with aluminum

are positive, a new test series without aluminum is conducted.

The American Society for Testing and Materials (1988a) adopted the U.S. Bureau of

Mines drop hammer method as their standard. Using a fixed drop hammer weight (2.0 or

3.0 kg), the drop height H,, giving 50% probability of a positive reaction is determined.

The lower is Hso,the more sensitivethe material is to impact ignition. In the test descrip-

tion, it is emphasized that the observation of the reaction of the sample is one of the dif-

ficult points in impact sensitivity testing. A positive test result is defined as an impact

that produces one or more of the following phenomena: (a) audible reaction, (b) flame

or visible light, (c) definite evidence of smoke (not to be confused with a dust cloud of

dispersed sample), and (d) definite evidence of discoloration of the sampledue to decom-

position. The problem arises with reactions that yield no distinguishableaudibleresponse,

no flame, and little sample consumption. The decision concerningreactiodno reaction in

these cases must be based primarily on the appearance of the sample after the test. The

impact in most cases compresses the sample into a thin disk, portions of which may

adhere to the striking tool surface,the anvil, or both. One should then inspect the tool and

anvil surfaces and look for voids in the powder disk and discoloration due to decompo-

sition in areas where voids occur. If there is discoloration from decomposition, the test

trial is to be consideredpositive. If there are smallvoids but no discoloration,the trial should