Page 542 - Dust Explosions in the Process Industries

P. 542

Assessment oflgnitability 509

FILTER PAPER

PERSPEX CYLINDER

d

ONE-WAY VALVE,

I '.I-

LsoLENoiD VALVES

AND TIMING SYSTEM

COMPRESSED AIR RESERVOIR

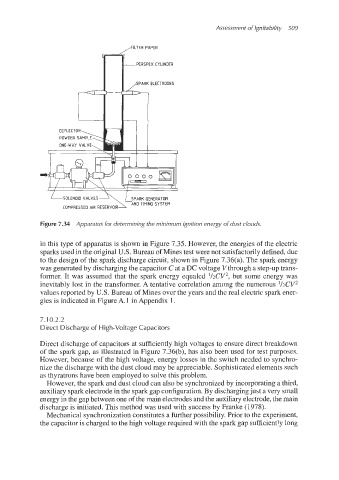

Figure 7.34 Apparatus for determining the minimum ignition energy ofdust clouds.

in this type of apparatus is shown in Figure 7.35. However, the energies of the electric

sparks used in the original U.S. Bureau of Mines test were not satisfactorilydefined, due

to the design of the spark discharge circuit, shown in Figure 7.36(a). The spark energy

was generatedby dischargingthe capacitor C at a DC voltage V through a step-up trans-

former. It was assumed that the spark energy equaled l/2CV2, but some energy was

inevitably lost in the transfomer. A tentative correlation among the numerous '/zCV2

values reported by U.S. Bureau of Mines over the years and the real electric spark ener-

gies is indicated in Figure A. 1 in Appendix 1.

7.1 0.2.2

Direct Discharge of High-Voltage Capacitors

Direct discharge of' capacitors at sufficiently high voltages to ensure direct breakdown

of the spark gap, as illustrated in Figure 7.36(b), has also been used for test purposes.

However, because 'of the high voltage, energy losses in the switch needed to synchro-

nize the discharge with the dust cloud may be appreciable. Sophisticatedelements such

as thyratrons have been employed to solve this problem.

However,the spark and dust cloud can also be synchronizedby incorporatinga third,

auxiliary spark electrode in the spark gap configuration. By dischargingjust a very small

energy in the gap between one of the main electrodes and the auxiliaryelectrode, the main

discharge is initiated. This method was used with success by Franke (1978).

Mechanical synchronizationconstitutes a further possibility. Prior to the experiment,

the capacitor is charged to the high voltage required with the spark gap sufficiently long