Page 545 - Dust Explosions in the Process Industries

P. 545

512 Dust Explosions in the Process Industries

w

WQ

+ 600

1

0

>

a

2 400

x

LL

Q a

v, 200

0

0 100 200 300 400 500

0.5

0.4

0.3

0.2

0.1

0.0

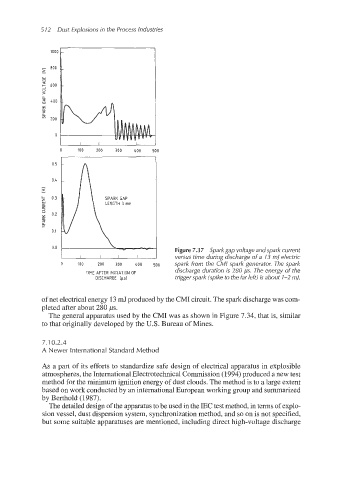

Figure 7.37 Spark gap voltage and spark current

versus time during discharge of a 13 mJ electric

0 100 200 300 400 500 spark from the CMI spark generator. The spark

discharge duration is 280 pi.The energy of the

TIME AFTER INITIATION OF

DISCHARGE [PSI trigger spark (spike to the far left) is about 1-2 mJ.

of net electrical energy 13mJproduced by the CMI circuit.The spark dischargewas com-

pleted after about 280 ,us.

The general apparatus used by the CMI was as shown in Figure 7.34, that is, similar

to that originally developed by the U.S. Bureau of Mines.

7.1 0.2.4

A Newer International Standard Method

As a part of its efforts to standardize safe design of electrical apparatus in explosible

atmospheres,the International Electrotechnical Commission (1994) produced a new test

method for the minimum ignition energy of dust clouds.The method is to a large extent

based on work conducted by an internationalEuropean working group and summarized

by Berthold (1987).

The detailed design of the apparatus to be used in the IEC test method, in terms of explo-

sion vessel, dust dispersion system, synchronization method, and so on is not specified,

but some suitable apparatuses are mentioned, including direct high-voltage discharge