Page 146 - Electric Drives and Electromechanical Systems

P. 146

Chapter 5 Brushed direct-current motors 139

The low mass of the rotor results in a low-inertia motor, permitting high accelera-

tions to be achieved. Due to the low inductance of the rotor winding, this type of

motor should be restricted to linear drives or very-high-frequency switched drives

to reduce any ripple current to a minimum.

5.2.2 Iron-rotor motors

Permanent-magnet iron-rotor motors have evolved directly from wound-rotor designs

and the design has been refined for servo applications. Due to the location of the

magnets and the large air gap which is required, these motors tend to be relatively long

with a small rotor diameter; this ensures that the motor’s inertia is minimised. The

manufacturers of these motors provide features that are designed to ensure ease of

application; these features include the provision of integral tachogenerators, encoders,

brakes, and fans, together with thermal trip indicators within the rotor windings. Due to

the widespread application of these motors, a range of standard sizes and fixings have

evolved; this considerably eases the procurement of the motors from a range of

manufacturers.

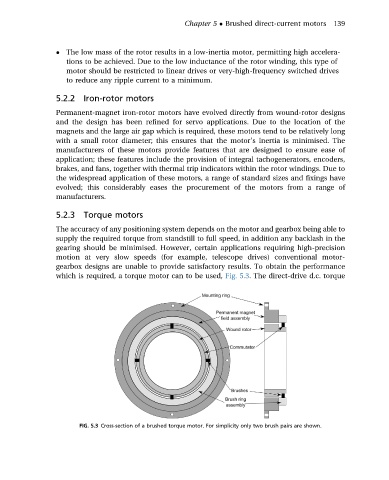

5.2.3 Torque motors

The accuracy of any positioning system depends on the motor and gearbox being able to

supply the required torque from standstill to full speed, in addition any backlash in the

gearing should be minimised. However, certain applications requiring high-precision

motion at very slow speeds (for example, telescope drives) conventional motor-

gearbox designs are unable to provide satisfactory results. To obtain the performance

which is required, a torque motor can to be used, Fig. 5.3. The direct-drive d.c. torque

FIG. 5.3 Cross-section of a brushed torque motor. For simplicity only two brush pairs are shown.