Page 255 - Electric Drives and Electromechanical Systems

P. 255

252 Electric Drives and Electromechanical Systems

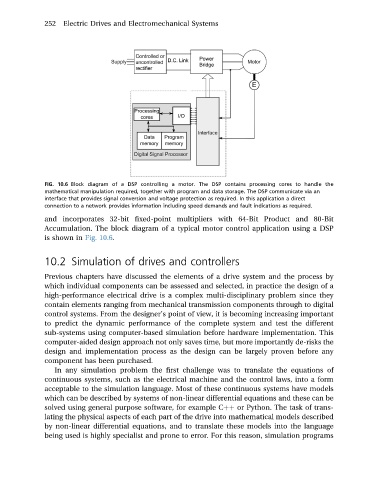

FIG. 10.6 Block diagram of a DSP controlling a motor. The DSP contains processing cores to handle the

mathematical manipulation required, together with program and data storage. The DSP communicate via an

interface that provides signal conversion and voltage protection as required. In this application a direct

connection to a network provides information including speed demands and fault indications as required.

and incorporates 32-bit fixed-point multipliers with 64-Bit Product and 80-Bit

Accumulation. The block diagram of a typical motor control application using a DSP

is shown in Fig. 10.6.

10.2 Simulation of drives and controllers

Previous chapters have discussed the elements of a drive system and the process by

which individual components can be assessed and selected, in practice the design of a

high-performance electrical drive is a complex multi-disciplinary problem since they

contain elements ranging from mechanical transmission components through to digital

control systems. From the designer’s point of view, it is becoming increasing important

to predict the dynamic performance of the complete system and test the different

sub-systems using computer-based simulation before hardware implementation. This

computer-aided design approach not only saves time, but more importantly de-risks the

design and implementation process as the design can be largely proven before any

component has been purchased.

In any simulation problem the first challenge was to translate the equations of

continuous systems, such as the electrical machine and the control laws, into a form

acceptable to the simulation language. Most of these continuous systems have models

which can be described by systems of non-linear differential equations and these can be

solved using general purpose software, for example Cþþ or Python. The task of trans-

lating the physical aspects of each part of the drive into mathematical models described

by non-linear differential equations, and to translate these models into the language

being used is highly specialist and prone to error. For this reason, simulation programs