Page 39 - Electric Drives and Electromechanical Systems

P. 39

Chapter 1 Electromechanical systems 31

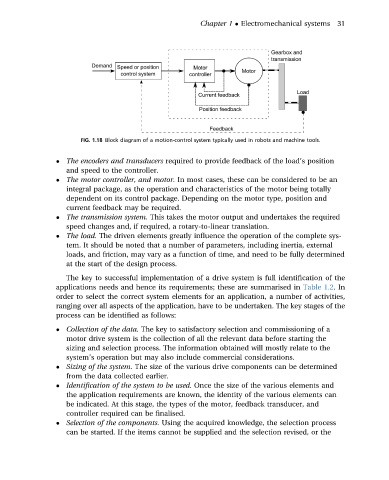

FIG. 1.18 Block diagram of a motion-control system typically used in robots and machine tools.

The encoders and transducers required to provide feedback of the load’s position

and speed to the controller.

The motor controller, and motor. In most cases, these can be considered to be an

integral package, as the operation and characteristics of the motor being totally

dependent on its control package. Depending on the motor type, position and

current feedback may be required.

The transmission system. This takes the motor output and undertakes the required

speed changes and, if required, a rotary-to-linear translation.

The load. The driven elements greatly influence the operation of the complete sys-

tem. It should be noted that a number of parameters, including inertia, external

loads, and friction, may vary as a function of time, and need to be fully determined

at the start of the design process.

The key to successful implementation of a drive system is full identification of the

applications needs and hence its requirements; these are summarised in Table 1.2.In

order to select the correct system elements for an application, a number of activities,

ranging over all aspects of the application, have to be undertaken. The key stages of the

process can be identified as follows:

Collection of the data. The key to satisfactory selection and commissioning of a

motor drive system is the collection of all the relevant data before starting the

sizing and selection process. The information obtained will mostly relate to the

system’s operation but may also include commercial considerations.

Sizing of the system. The size of the various drive components can be determined

from the data collected earlier.

Identification of the system to be used. Once the size of the various elements and

the application requirements are known, the identity of the various elements can

be indicated. At this stage, the types of the motor, feedback transducer, and

controller required can be finalised.

Selection of the components. Using the acquired knowledge, the selection process

can be started. If the items cannot be supplied and the selection revised, or the