Page 37 - Electric Drives and Electromechanical Systems

P. 37

Chapter 1 Electromechanical systems 29

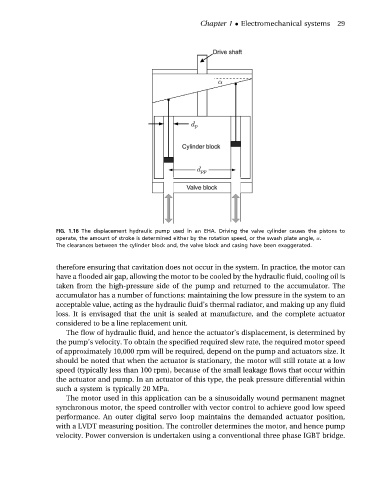

FIG. 1.16 The displacement hydraulic pump used in an EHA. Driving the valve cylinder causes the pistons to

operate, the amount of stroke is determined either by the rotation speed, or the swash plate angle, a.

The clearances between the cylinder block and, the valve block and casing have been exaggerated.

therefore ensuring that cavitation does not occur in the system. In practice, the motor can

have a flooded air gap, allowing the motor to be cooled by the hydraulic fluid, cooling oil is

taken from the high-pressure side of the pump and returned to the accumulator. The

accumulator has a number of functions: maintaining the low pressure in the system to an

acceptable value, acting as the hydraulic fluid’s thermal radiator, and making up any fluid

loss. It is envisaged that the unit is sealed at manufacture, and the complete actuator

considered to be a line replacement unit.

The flow of hydraulic fluid, and hence the actuator’s displacement, is determined by

the pump’s velocity. To obtain the specified required slew rate, the required motor speed

of approximately 10,000 rpm will be required, depend on the pump and actuators size. It

should be noted that when the actuator is stationary, the motor will still rotate at a low

speed (typically less than 100 rpm), because of the small leakage flows that occur within

the actuator and pump. In an actuator of this type, the peak pressure differential within

such a system is typically 20 MPa.

The motor used in this application can be a sinusoidally wound permanent magnet

synchronous motor, the speed controller with vector control to achieve good low speed

performance. An outer digital servo loop maintains the demanded actuator position,

with a LVDT measuring position. The controller determines the motor, and hence pump

velocity. Power conversion is undertaken using a conventional three phase IGBT bridge.