Page 97 - Electric Drives and Electromechanical Systems

P. 97

90 Electric Drives and Electromechanical Systems

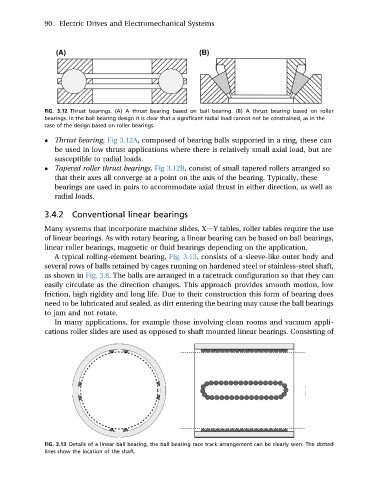

FIG. 3.12 Thrust bearings. (A) A thrust bearing based on ball bearing. (B) A thrust bearing based on roller

bearings. In the ball bearing design it is clear that a significant radial load cannot not be constrained, as in the

case of the design based on roller bearings.

Thrust bearing, Fig 3.12A, composed of bearing balls supported in a ring, these can

be used in low thrust applications where there is relatively small axial load, but are

susceptible to radial loads.

Tapered roller thrust bearings, Fig 3.12B, consist of small tapered rollers arranged so

that their axes all converge at a point on the axis of the bearing. Typically, these

bearings are used in pairs to accommodate axial thrust in either direction, as well as

radial loads.

3.4.2 Conventional linear bearings

Many systems that incorporate machine slides, XdY tables, roller tables require the use

of linear bearings. As with rotary bearing, a linear bearing can be based on ball bearings,

linear roller bearings, magnetic or fluid bearings depending on the application.

A typical rolling-element bearing, Fig. 3.13, consists of a sleeve-like outer body and

several rows of balls retained by cages running on hardened steel or stainless-steel shaft,

as shown in Fig. 3.8. The balls are arranged in a racetrack configuration so that they can

easily circulate as the direction changes. This approach provides smooth motion, low

friction, high rigidity and long life. Due to their construction this form of bearing does

need to be lubricated and sealed, as dirt entering the bearing may cause the ball bearings

to jam and not rotate.

In many applications, for example those involving clean rooms and vacuum appli-

cations roller slides are used as opposed to shaft mounted linear bearings. Consisting of

FIG. 3.13 Details of a linear ball bearing, the ball bearing race track arrangement can be clearly seen. The dotted

lines show the location of the shaft.