Page 154 - Electrical Equipment Handbook _ Troubleshooting and Maintenance

P. 154

MAINTENANCE OF MOTORS

MAINTENANCE OF MOTORS 8.9

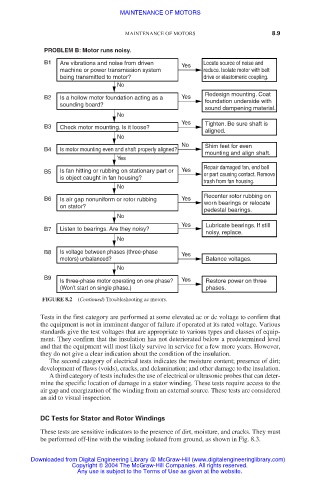

PROBLEM B: Motor runs noisy.

B1 Are vibrations and noise from driven Yes Locate source of noise and

machine or power transmission system reduce. Isolate motor with belt

being transmitted to motor? drive or elastomeric coupling.

No

Redesign mounting. Coat

B2 Is a hollow motor foundation acting as a Yes foundation underside with

sounding board?

sound dampening material.

No

Yes Tighten. Be sure shaft is

B3 Check motor mounting. Is it loose?

aligned.

No

No Shim feet for even

B4 Is motor mounting even and shaft properly aligned?

mounting and align shaft.

Yes

Repair damaged fan, end bell

B5 Is fan hitting or rubbing on stationary part or Yes or part causing contact. Remove

is object caught in fan housing?

trash from fan housing.

No

Recenter rotor rubbing on

B6 Is air gap nonuniform or rotor rubbing Yes

worn bearings or relocate

on stator?

pedestal bearings.

No

Yes Lubricate bearings. If still

B7 Listen to bearings. Are they noisy?

noisy, replace.

No

B8 Is voltage between phases (three-phase Yes

motors) unbalanced? Balance voltages.

No

B9 Yes

Is three-phase motor operating on one phase? Restore power on three

(Won’t start on single phase.) phases.

FIGURE 8.2 (Continued) Troubleshooting ac motors.

Tests in the first category are performed at some elevated ac or dc voltage to confirm that

the equipment is not in imminent danger of failure if operated at its rated voltage. Various

standards give the test voltages that are appropriate to various types and classes of equip-

ment. They confirm that the insulation has not deteriorated below a predetermined level

and that the equipment will most likely survive in service for a few more years. However,

they do not give a clear indication about the condition of the insulation.

The second category of electrical tests indicates the moisture content; presence of dirt;

development of flaws (voids), cracks, and delamination; and other damage to the insulation.

A third category of tests includes the use of electrical or ultrasonic probes that can deter-

mine the specific location of damage in a stator winding. These tests require access to the

air gap and energization of the winding from an external source. These tests are considered

an aid to visual inspection.

DC Tests for Stator and Rotor Windings

These tests are sensitive indicators to the presence of dirt, moisture, and cracks. They must

be performed off-line with the winding isolated from ground, as shown in Fig. 8.3.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.