Page 152 - Electrical Installation in Hazardous Area

P. 152

1 18 Electrical installations in hazardous areas

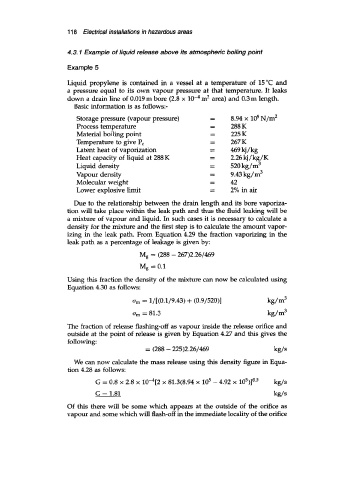

4.3.1 Example of liquid release above its atmospheric boiling point

Example 5

Liquid propylene is contained in a vessel at a temperature of 15°C and

a pressure equal to its own vapour pressure at that temperature. It leaks

down a drain line of 0.019 m bore (2.8 x m2 area) and 0.3 m length.

Basic information is as follows:-

Storage pressure (vapour pressure) 8.94 x 105N/m2

Process temperature 288 K

Material boiling point 225 K

Temperature to give P, 267 K

Latent heat of vaporization 469 kj / kg

Heat capacity of liquid at 288K 2.26 kj / kg /K

Liquid density 520 kg/m3

Vapour density 9.43 kg/m3

Molecular weight 42

Lower explosive limit 2% in air

Due to the relationship between the drain length and its bore vaporiza-

tion will take place within the leak path and thus the fluid leaking will be

a mixture of vapour and liquid. In such cases it is necessary to calculate a

density for the mixture and the first step is to calculate the amount vapor-

izing in the leak path. From Equation 4.29 the fraction vaporizing in the

leak path as a percentage of leakage is given by:

M, = (288 - 267)2.26/469

M, = 0.1

Using this fraction the density of the mixture can now be calculated using

Equation 4.30 as follows:

a, = 1/[(0.1/9.43) + (0.9/520)] kg/m3

0, = 81.3 kg/m3

The fraction of release flashing-off as vapour inside the release orifice and

outside at the point of release is given by Equation 4.27 and this gives the

following:

= (288 - 225)2.26/469 kg/s

We can now calculate the mass release using this density figure in Equa-

tion 4.28 as follows:

G = 0.8 x 2.8 x 10-~[2 x 81.q8.94 x io5 - 4.92 x 105)]0.5 kg/s

G = 1.81 kg/s

Of this there will be some which appears at the outside of the orifice as

vapour and some which will flash-off in the immediate locality of the orifice