Page 81 - Electrical Installation in Hazardous Area

P. 81

Area classification for gases, vapours and mists 57

\\\\\\\\\\\\\\\\\\ T

............... ...........................

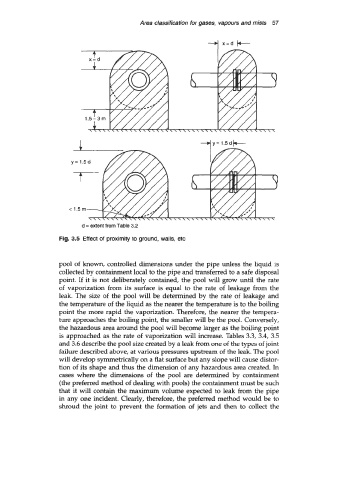

d =extent from Table 3.2

Fig. 3.5 Effect of proximity to ground, walls, etc

pool of known, controlled dimensions under the pipe unless the liquid is

collected by containment local to the pipe and transferred to a safe disposal

point. If it is not deliberately contained, the pool will grow until the rate

of vaporization from its surface is equal to the rate of leakage from the

leak. The size of the pool will be determined by the rate of leakage and

the temperature of the liquid as the nearer the temperature is to the boiling

point the more rapid the vaporization. Therefore, the nearer the tempera-

ture approaches the boiling point, the smaller will be the pool. Conversely,

the hazardous area around the pool will become larger as the boiling point

is approached as the rate of vaporization will increase. Tables 3.3, 3.4, 3.5

and 3.6 describe the pool size created by a leak from one of the types of joint

failure described above, at various pressures upstream of the leak. The pool

will develop symmetrically on a flat surface but any slope will cause distor-

tion of its shape and thus the dimension of any hazardous area created. In

cases where the dimensions of the pool are determined by containment

(the preferred method of dealing with pools) the containment must be such

that it will contain the maximum volume expected to leak from the pipe

in any one incident. Clearly, therefore, the preferred method would be to

shroud the joint to prevent the formation of jets and then to collect the