Page 123 - Electromechanical Devices and Components Illustrated Sourcebook

P. 123

Chapter 5 Magnetic Components 85

Transformers The output voltage of a transformer is a function of the

ratio of the number of windings of the primary to the sec-

By placing two coils in close proximity to one other it is pos- ondary. By adjusting the number of turns, a transformer can

sible to achieve magnetic coupling. The first coil (primary) is produce either lower or higher output voltages. The trans-

connected to a power source and the second coil (secondary) former in Figure 5-5 has a 2500-turn primary and a 500-turn

is connected to a / voltmeter. Each time the power to the secondary. This arrangement will produce a 24-volt output

primary is turned on and off, the magnetic field is raised or with a 120-volt input. Inversely, if roles of the coils are

collapsed. As the magnetic field is raised and collapsed, a reversed the output would produce 600 volts for a 120-volt

voltage is induced in the secondary coil and the meter will input. To calculate the output voltage of a simple transformer

deflect. Figure 5-4 shows two coils that are inductively cou- divide the input voltage by the ratio of the coils.

pled. Coils set up in this manner constitute a transformer.

output volts input volts (number of primary turns

number of secondary turns)

As an example, if a transformer has a 10,000-turn primary,

Push Button

a 500-turn secondary, and is receiving 480-volt input the out-

+ − Voltmeter put will be 24 volts.

24 volts 480 volts (10,000 turns 500 turns)

Battery

Most commercial transformers are built around a lami-

nated “E” frame core. The laminations are stamped pieces of

Primary Secondary sheet metal in the shape of the letter E. The laminations are

Coil Coil stacked to produce the necessary mass of iron for any given

design. The two “E” sections are assembled with the coil

around the middle leg, as shown in Figure 5-6. To improve

Air Gap magnetic coupling between the two “E” sections, some

Figure 5-4 Magnetic or Inductive Coupling designs overlap the laminations on the outside legs.

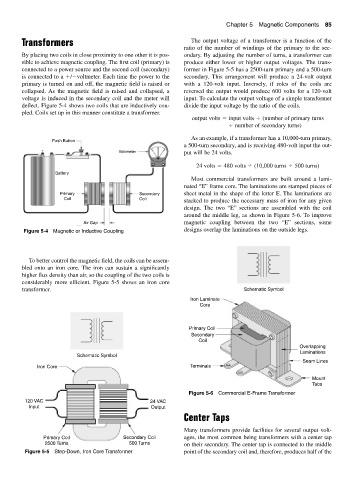

To better control the magnetic field, the coils can be assem-

bled onto an iron core. The iron can sustain a significantly

higher flux density than air, so the coupling of the two coils is

considerably more efficient. Figure 5-5 shows an iron core

transformer. Schematic Symbol

Iron Laminate

Core

Primary Coil

Secondary

Coil

Overlapping

Laminations

Schematic Symbol

Seam Lines

Iron Core Terminals

Mount

Tabs

Figure 5-6 Commercial E-Frame Transformer

120 VAC 24 VAC

Input Output

Center Taps

Many transformers provide facilities for several output volt-

Primary Coil Secondary Coil ages, the most common being transformers with a center tap

2500 Turns 500 Turns on their secondary. The center tap is connected to the middle

Figure 5-5 Step-Down, Iron Core Transformer point of the secondary coil and, therefore, produces half of the