Page 188 - Electromechanical Devices and Components Illustrated Sourcebook

P. 188

150 Electromechanical Devices & Components Illustrated Sourcebook

When considering the type of electrical connectors to use in extremely common in home, commercial, and industrial

any system, one is faced with a dizzying array of different power distribution systems. A wire nut will typically have

designs to select from. In the absence of any real knowledge three elements for joining the wires, a thread insert, a transi-

about what applications different connectors are designed for, tion, and insulation threads. The thread insert is normally a

it can become a daunting task to sift through the literally thou- diamond-shaped piece of spring steel coiled into a taper and

sands of different configurations currently on the market. This molded into the body. The sharp edges of the shape cut into

chapter of the book reviews the different methods and the most the wire and the taper forces the wires together. This assures

common connectors used for connecting electrical circuits. It a high quality, low resistance connection. Larger wire nuts

will provide base level knowledge and make the task of select- have grip wings molded into the body to provide the neces-

ing connectors and connection types a little less daunting. sary torque to join heavier wires. The transition is a cone that

is intended to guide the wires into the wire threads. The lower

threads are intended to engage the wire insulation and prevent

Twisted Connections it from sliding back and exposing the conductor. The body of

the wire nut is made from high-impact plastic.

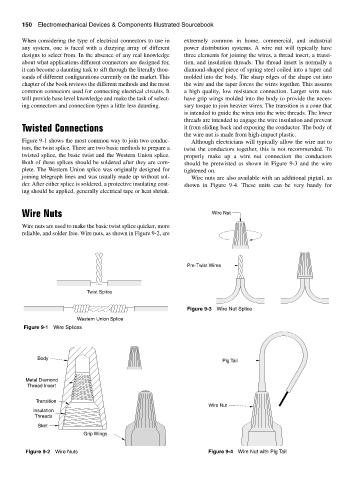

Figure 9-1 shows the most common way to join two conduc- Although electricians will typically allow the wire nut to

tors, the twist splice. There are two basic methods to prepare a twist the conductors together, this is not recommended. To

twisted splice, the basic twist and the Western Union splice. properly make up a wire nut connection the conductors

Both of these splices should be soldered after they are com- should be pretwisted as shown in Figure 9-3 and the wire

plete. The Western Union splice was originally designed for tightened on.

joining telegraph lines and was usually made up without sol- Wire nuts are also available with an additional pigtail, as

der. After either splice is soldered, a protective insulating coat- shown in Figure 9-4. These units can be very handy for

ing should be applied, generally electrical tape or heat shrink.

Wire Nuts Wire Nut

Wire nuts are used to make the basic twist splice quicker, more

reliable, and solder free. Wire nuts, as shown in Figure 9-2, are

Pre-Twist Wires

Twist Splice

Figure 9-3 Wire Nut Splice

Western Union Splice

Figure 9-1 Wire Splices

Body

Pig Tail

Metal Diamond

Thread Insert

Transition

Wire Nut

Insulation

Threads

Skirt

Grip Wings

Figure 9-2 Wire Nuts Figure 9-4 Wire Nut with Pig Tail