Page 190 - Electromechanical Devices and Components Illustrated Sourcebook

P. 190

152 Electromechanical Devices & Components Illustrated Sourcebook

Hydraulic

aoi

Pneumatic

Aviation

6-32 Wire

4-40 Cutter

18 14 10 10-24

22 16 12 10-32

8-32 Ignition Wire Stripper

Terminals

Electrical Utility Pliers

Ratchet

Strike Block & Punch

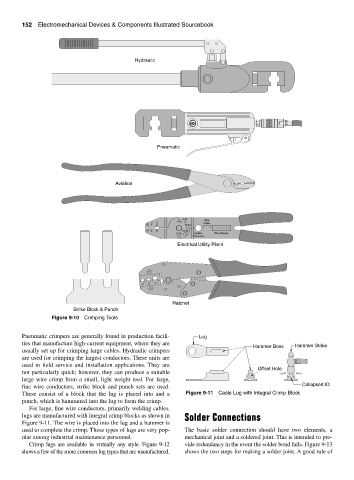

Figure 9-10 Crimping Tools

Pneumatic crimpers are generally found in production facili- Lug

ties that manufacture high-current equipment, where they are

Hammer Boss Hammer Strike

usually set up for crimping large cables. Hydraulic crimpers

are used for crimping the largest conductors. These units are

used in field service and installation applications. They are

Offset Hole

not particularly quick; however, they can produce a suitable

large wire crimp from a small, light weight tool. For large,

fine wire conductors, strike block and punch sets are used. Collapsed ID

These consist of a block that the lug is placed into and a Figure 9-11 Cable Lug with Integral Crimp Block

punch, which is hammered into the lug to form the crimp.

For large, fine wire conductors, primarily welding cables,

lugs are manufactured with integral crimp blocks as shown in Solder Connections

Figure 9-11. The wire is placed into the lug and a hammer is

used to complete the crimp. These types of lugs are very pop- The basic solder connection should have two elements, a

ular among industrial maintenance personnel. mechanical joint and a soldered joint. This is intended to pro-

Crimp lugs are available in virtually any style. Figure 9-12 vide redundancy in the event the solder bond fails. Figure 9-13

shows a few of the more common lug types that are manufactured. shows the two steps for making a solder joint. A good rule of